Research Progress on the Development and Application of Three Dimensional Polymer Nanocomposites

Editor: | Jul 11,2018

Polymer nanocomposites is one of the most emerging fields in material science and engineering. Novel carbon-based materials, represented by carbon nanotubes (CNTs) and graphene, have attracted much attention todevelope polymer nanocomposites because of their unique structures and excellent properties. How to disperse the nanoparticles into a polymer and stabilize these dispersed particles in matrix are the key issues for the preparation of polymer nanocomposites with enhanced properties. By utilizing the large surface area of nanoparticles, it is possible to construct foam-like architecture, thus providing anew alternative to prepare high performance polymer nanocomposites. Chemical vapor deposition (CVD) method is an effective strategy to develop such structure, however, this method generally uses metal foam as a template, and the substrate has to be removed by strong acid after preparation, leading to some negative effects on the structure and properties of nanoparticles.

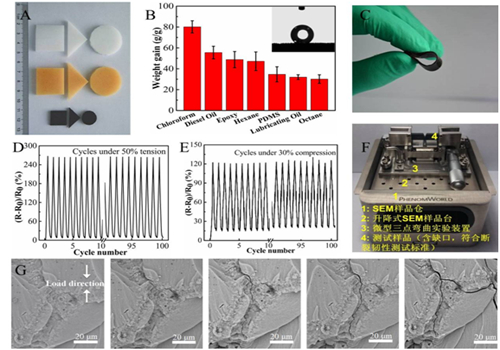

A team working on composite materials led by Professor Peng-Cheng Ma in the Xinjiang Technical Institute of Physics and Chemistry, Chinese Academy of Science, has made progress on developing CNT foam by using commercial polymer foam as a template. Unlike the traditional methods for the preparation of foam-like CNTs, the new onecombined a 3-in-1 step, i.e., decomposition/removal of the template, generation of the metal catalyst and CNT growth, for efficient and scaled-up production of CNT foam (Figure 1A). The developed material showed a hydrophobic property and could adsorb a variety of polymers and organic compounds by 30 to 80 times its own weight (Figure 1B), allowing convenient preparation of nanocomposites and eliminating the problems associated with the dispersion of nanofillers in the polymer matrix. The developed method also shows excellent applicability, for example, when taking cotton or graphene foam as a template, CNT materials with hierarchical or hybrid structures were achieved, respectively.

By utilizing the porous structure and excellent adsorption performance of foam, three dimensional polymer nanocomposites reinforced with CNT foam was fabricated via the self-infusion of polydimethylsiloxane (Figure 1C). The researchers studied the mechanical and electrical properties of nanocomposites, and found that the material exhibited a piezoresistivebehavior under the mechanical deformation. A prototype flexible sensor was designed based on the nanocomposites, and the device was sensitive to both compressive and tensile strains. Such performance could besustained with outstanding stability under the cyclic runs (D and E in Figure 1).The operating principle of the sensor was investigated as well by using a specially-made fixture (Figure 1F), and the results revealed that the device’s piezoresistivity was closely related to the changes in the angles around the joints and the length of the struts of the constructed cells in the CNT foam, which resulted in the initiation and propagation of cracking/damage in the nanocomposites (Figure 1G). The combination of the rapid response and excellent flexibility/stability of three dimensional polymer nanocomposites meant that the developed sensor could monitor the motion of a finger and serve as an electronic skin to display the distribution of pressure, suggesting the great potential of the nanocomposites for the applications in wearable and flexible electronics, energy storage and so on.

Part of research outputs has been patented, and the results on the flexible sensor using three dimensional polymer nanocomposites were published in Composites Science and Technology. The project was supported by the National Nature ScienceFoundation of China, the National 1000-TalentProgram, as well as the Research Fund from the Alliance of Special FineChemical Innovation and Industrialization in CAS.

1. Stretchable and compressible strain sensor based on carbon nanotube foam/polymer nanocomposites with three dimensional networks. Composites Science and Technology, 2018, 163, 162-170 (Science Direct).

2. Carbon nanotubes on highly interconnected carbonized cotton for flexible and light-weight energy storage. Advanced Sustainable System, 2017, 1700022 (Online Library).

3. Preparation of carbon nanotubes/graphene hybrid aerogel and itsapplication for the adsorption of organic compounds. Carbon, 2017, 118, 765-771 (Science Direct)

Figure 1. Preparation and application of three dimensional polymer nanocomposites (A: Foam samples of polymer and CNTs; B: The adsorption capacity of CNT foam; C: Flexible CNT foam/PDMS polymer nanocomposites; D and E: Piezoresistive behavior of flexible sensor under cyclic tensile and compressive strains; F: A fixture used for the in-situ study of fracture behavior of nanocomposites under the mechanical deformation; G: Initiation and propagation of cracks in three dimensional polymer nanocomposites).

Contact:

Prof. MA Pengcheng

E-mail:mapc@ms.xjb.ac.cn

Xinjiang Technical Institute of Physics & Chemistry, CAS

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina