Breakthrough Development in the Separation of Oil-Water Emulsions by Electrocoagulation (EC) Process

Editor: | Aug 17,2022

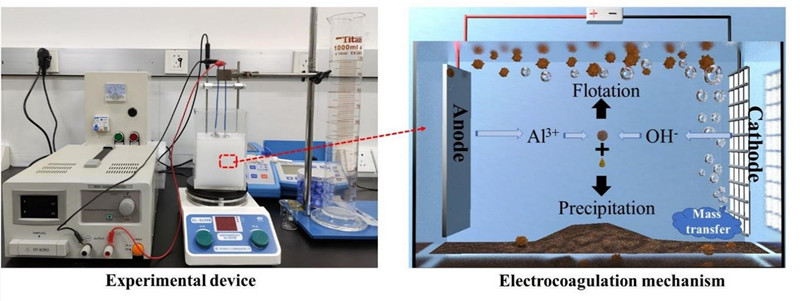

The electrocoagulation (EC) process is beneficial in wastewater treatment, especially for treatment oil wastewater. As a continuation of the traditional drilling and perforated electrode, SS mesh as cathode material, has good chemical corrosion resistance such as acid, alkali, and salt resistance, which can reduce the frequency of replacing electrode materials and gives it stable electrochemical performance. Apart from that, the well-organized pore size structure of SS mesh increases the mass transfer as well as faster heat dissipation in the EC process, which is beneficial for reducing energy consumption (associated to the agitator energy required for the mass transfer process), and for reduction of heat evolved & electrode passivation especially in treating high COD load wastewaters.

To check this hypothesis, a research group of separation materials and technology at Xinjiang Technical Institute of Physics & Chemistry, Chinese Academy of Sciences (CAS) proposed a new batch scale EC reactor with Al plate anode and SS mesh (304) cathode combination. To date, of the total of research studies, there is no a comprehensive reported work on such electrode combination in ECs for the separation of oil-in-water emulsions. As oil separation efficiency and operation cost are hugely dependent on the various parameters in EC process. Therefore, a central composite design (CCD) technique of response surface method (RSM) was applied to optimize crucial factors such as pH, the applied voltage (V), and working time (min) in EC. Under optimized conditions, the maximum COD removal rate of 90.86% from synthetic oil-water emulsions was obtained. The corresponding electrical energy and electrode consumptions during the EC were determined as 1.54 kWh/kg-COD and 0.66 kg/m3. An important point to note is that energy consumption in the present study was comparable with previous studies. According to SEM-EDS, XRD, and FTIR analysis results, the sludge contains NaCl crystals and aluminum hydroxide polymer (AlOOH), which represents remarkable roughness and rich network constructure. The results demonstrated that the electrode combination of Aluminum plate as anode and SS mesh (304) as cathode showed better oil-water removal efficiency of EC process.

This research progress was published in Chemical Engineering and Processing - Process Intensification Journal entitled as “Performance optimization of a batch scale electrocoagulation process using stainless steel mesh (304) cathode for the separation of oil-in-water emulsion”. This work was financially supported by Chinese Academy of Sciences (CAS) Special Research Assistant Project and the West Light Foundation of CAS, as well as the Program for Attracting High-Level Talents in Xingjiang Uyghur Autonomous Region.

Article Link:https://doi.org/10.1016/j.cep.2022.108901

Fig. 1: The EC experimental set-up (A) and electrocoagulation mechanism (B).

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina