To reduce the effects of global warming and severe environmental pollution, different forms of clean energy carrier such as hydrogen (H2), methane (CH4) and ethanol (C2H5OH) are sought to replace conventional energy sources. Among them, H2 is considered the cleanest energy carrier, because when it burns it emits no toxic gases, and it has a higher energy density (up to 142 MJ/kg) than most other energy sources, together with liquefied natural gas (54.4 MJ/kg), bioethanol (29.5 MJ/kg), and CH4 (50.0 MJ/kg), and has a wider range of applications. In Indonesia, Malaysia, and Thailand, the Palm Oil industry leads to the production of enormous quantities of palm oil mill effluent (POME). Researchers have developed several methods such as water electrolysis, bio-photolysis, photo-fermentation, dark fermentation, pyrolysis, anaerobic digestion, and gasification to generate H2 from carbohydrate-rich organic wastewater for commercial use. However, over the past decades, these methods for producing H2 from POME wastewater have had low yields and the treated wastewater has had difficulty satisfy the criteria for discharge limitations. Therefore, it is of great environmental importance to find a method that allows both treating wastewater and simultaneously enhance H2 production to reduce energy consumption.

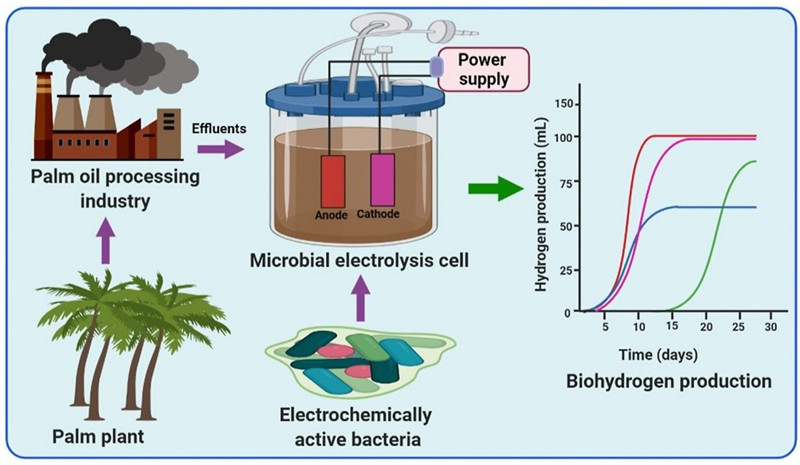

Based on the above considerations, Separation Materials and Technology research team of Xinjiang Technical Institute of Physics and Chemistry (XTIPC), Chinese Academy of Sciences (CAS), and collaborative research team from abroad, employed microbial electrolysis cell (MEC, a new bio-electrochemical method for converting organic matter to hydrogen gas H2 to treat Palm oil mill effluent (POME). The electrochemically active microorganisms in the MEC consume organic matter in the wastewater during its metabolic process, and electrons are first transferred from the intracellular to the extracellular anode, and then reach to the cathode through the action of the potential difference provided by the external circuit power supply, and generate H2 by combining electrons and protons, thus achieving the degradation of organic matter in the wastewater and the purpose of the generate H2.

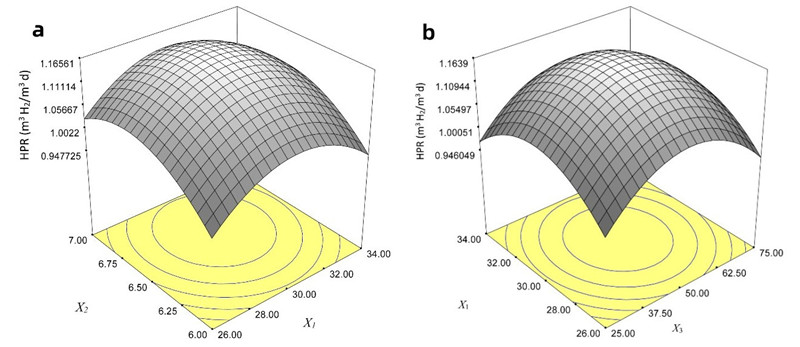

To enhance bio-hydrogen generation from POME in the MEC, an empirical model was generated by using response surface methodology (RSM). A central composite design (CCD) was utilized to perform set of twenty experimental runs of MEC given three important variables, namely: incubation temperature, initial pH, and influent dilution rate (COD). CCD experimental results showed that an average value of 1.16 m3 H2/m3 d for maximum hydrogen production rate (HPR) was obtained. A second-order polynomial model was adjusted to the experimental results from CCD. The regression model showed that the quadratic term of all variables tested had a highly significant effect (P < 0.01) on maximum HPR as a defined response. The analysis of the empirical model revealed that the optimal conditions for maximum HPR were incubation temperature, initial pH, and influent dilution rate of 30.23°C, 6.63, and 50.71%, respectively. Generated regression model predicted a maximum HPR of 1.1659 m3 H2/m3 d under optimum conditions. Validation experiment was conducted in the determined optimal conditions. Experimental results of the validation test showed that a maximum HPR of 1.1747 m3 H2/m3 d was achieved. The values are highly in agreement with the predicted values by RSM-CCD model. This novel method of treating oily wastewater while producing clean energy (H2) provides the basis for energy production and environmental protection research, and provides an important experimental and theoretical basis for design and applications in industry.

The paper was published in Int. J. Hydrogen Energy. 2022, 47, 15464-15479 with the title of “Performance optimization of microbial electrolysis cell (MEC) for palm oil mill effluent (POME) wastewater treatment and sustainable Bio-H2 production using response surface methodology (RSM)”. This work was supported by Chinese Academy of Sciences Special Research Assistant Project, Project No: E15R6301. This work also was supported by the National University of Malaysia (UKM), Project No: DIP-2017-019 and the Malaysian Ministry of Higher Education (MOHE).

The concurrent effect of (A) temperature °C(X1) and initial pH(X2) and (B) temperature (X1) and influent COD concentration% (X3) on the maximum volumetric HPR of MEC.

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina