XTIPC -University of Guanajuato in Mexico collaborative research on the treatment of post-tanning wastewater by electrocoagulation process

Editor: | Aug 30,2022

The tanning process is usually divided into three stages: preparation, tanning, and dressing/finishing. Within latter, the post-tanning process is present, where re-tanning, dyeing, bleaching, and fat liquoring take place. Post-tanning, different chemicals are used; including tannins and resins, greases and oils, and dyes. Due to variation in input materials, processes, chemicals, and water consumption, chemical load and residues change greatly, wastewater characterization should be followed. Dyes are usually present in post-tanning wastewater, whose characteristics depend on daily needs and have the potential to exacerbate the toxicity of the water due to their ability to bind to ions in the wastewater. Therefore, separate treatment methods are applied to each process within the tannery, such as post-tanning wastewater, and in addition to biological treatment, innovative processes can be applied to treat tannery wastewater, such as Anodic-oxidation (AO), Electro-Fenton (EF), Photo-catalysis, adsorption. However, these processes can be costly and require long treatment times. Therefore electrocoagulation (EC) treatment is considered suitable. Although efficiency of the EC is strongly influenced by the electrode material, suitable electrodes make it an ideal treatment process. For instance, some cases using carbon steel electrodes can effectively generate coagulants in situ at the anode by applying a potential difference and can remove pollutants by coagulation, flocculation, and sedimentation. However, in the past, wastewater from different tanning stages were mixed for treatment, but in the actual tanning industry, not all stages are present in most plants, which affects the medium of treatment. Therefore, the use of carbon-steel-iron electrodes and the study of the influence of each parameter in continuous flow wastewater treatment in EC systems is informative for real wastewater.

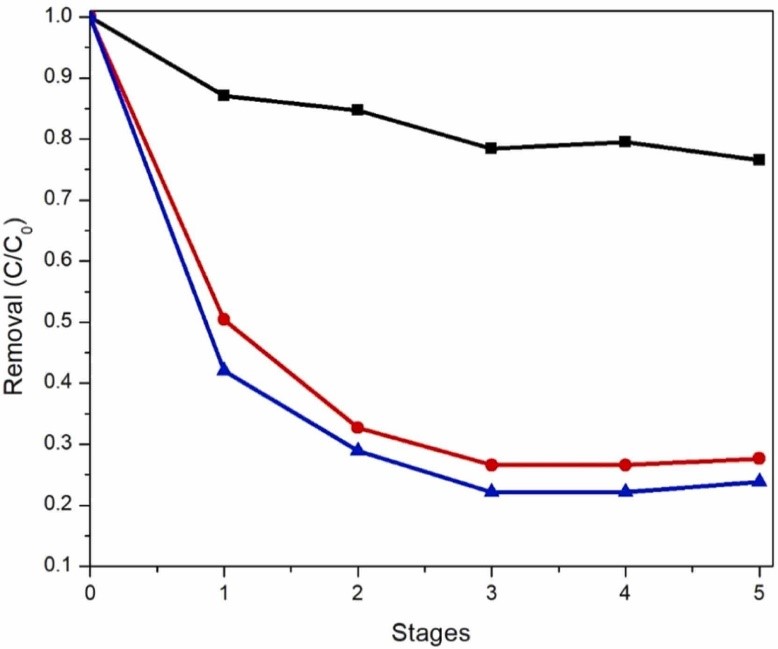

Based on this, the separation materials and technology research team of Xinjiang Technical Institute of Physics and Chemistry (XTIPC), and collaborative research team from University of Guanajuato in Mexico, used continuous flow electrocoagulation (EC) with carbon steel electrodes to treat post-tanning wastewater. In order to investigate the effects of each parameter, response surface method (RSM) based on central composite design (RSM-CCD) was used for variable optimization and analysis of variance. Under the optimal conditions of initial pH 3.0, current density 6.4 mA/ m2, initial dye concentration 125 mg/ L, NaCl concentration 1000 mg /L, and inlet flow rate 176 mL /min, the dye removal rate was 71%, operating cost (OC) 0.05 US$ /m3, power consumption 1.3 kWh /m3, and electrode consumption 0.05 kg /m3. Moreover, the ability to remove dyes per mg of dissolved iron (qe) 4.3 mg Dye /L/ C and total dissolved solids (TDS) removal (43.5%) were investigated,it also proves that carbon steel electrode is feasible to treat tannery wastewater as the electrode of EC process. Optimal process conditions were used to treat real post-tanning wastewater with chemical oxygen demand (COD) and TDS removal rates of 23% and 76%, respectively, yielding lower OC (0.84 US$/m3) and some energy consumption of (20.6 kWh/m3). Furthermore, the kinetic modeling study found that the pseudo-first-order kinetic model matched the experimental results with an electrical energy per stage (EEO) of 1 kW h/m and a higher k value (1.14 /min). The researchers proved that the presence of iron nanoparticles in the sludge by scanning electron microscopy analysis. All input and output parameters were statistically significant, with indicators such as TDS and qe being valuable for the effective removal of pollutants and for determining the increase in TDS in the treated water. The outcomes of this study showed that EC is a suitable method for treating post-tanning wastewater, and providing further knowledge of steel-carbon EC reactor design and the purpose of sludge reuse to provide new ideas and foundation for the application of EC reactor to treat actual post-tanning wastewater.

The relevant research results were published in the Journal Process Safety and Environmental Protection (Process Saf. Environ Prot., 2022, 165, 872-886). This research work was supported by the Shanghai Cooperation Organization Science and Technology Partnership Program and the International Science and Technology Cooperation Program [Grant number: 2022E01015]. And the economic support from Universidad de Guanajuato under grant 013/2022.

Article:https://doi.org/10.1016/j.psep.2022.08.008

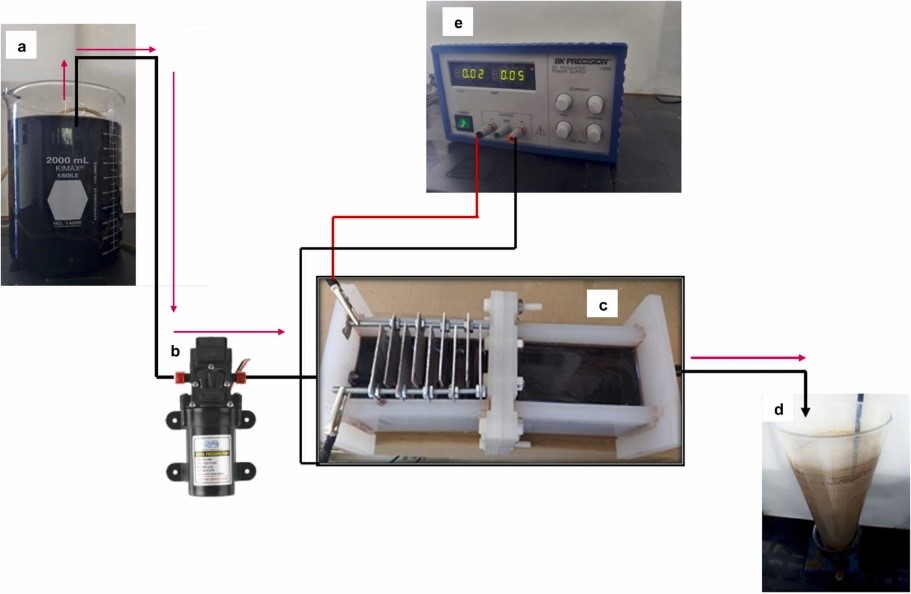

Fig. 1: (a) 2L reservoir, (b) peristaltic pump, (c) electrocoagulation reactor, (d) imhoff cone, (e) power supply.

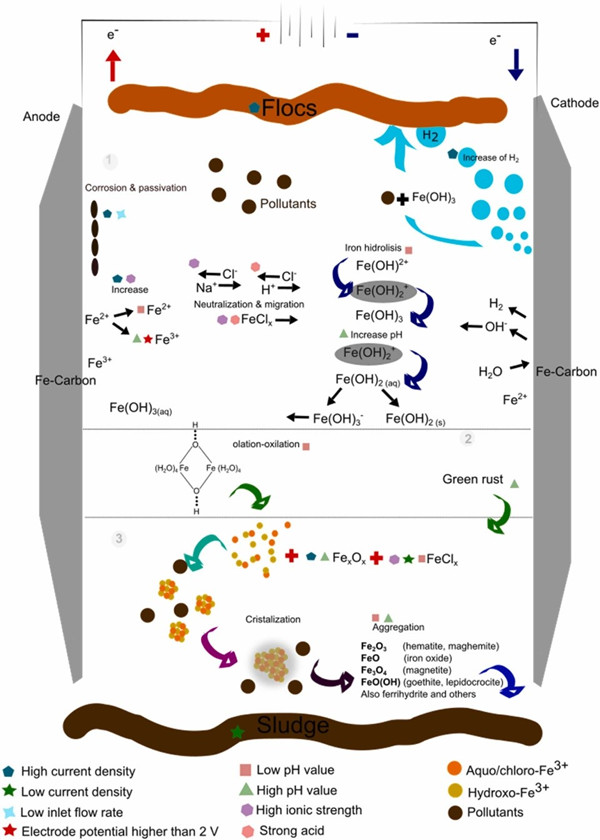

Fig. 2. Electrocoagulation process-carbon steel electrodes within parameter changes

Fig. 3: Real post-tanning wastewater using continuous electrocoagulation DQO (mg/L) (Black line), Conductivity (mS/cm) (

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina