XTIPC Make Research progress on Wastewater Treatment and Sustainable Hydrogen Production by Microbial Electrolysis Cell Technology

Editor: | Oct 13,2022

The rapidly growth in world's population, economy and urbanization not only have resulted in an increased global energy demand, but also have caused more pollution of air and water resources. Due to a regulatory requirement on the discharge of pollutants, wastewater treatment to hydrogen (H2) research has gained a wider scope. Among numerous energy sources, Hydrogen (H2) is considered a promising future green fuel due to its superior energy content per unit weight (142 kJ g?1 or 61, 000 Btu lb?1), however its production from non-renewable sources (fossil fuels) is not eco-friendly. Therefore, higher H2 yielding cleaner technologies must be explored to meet reasonable expectations of global decarbonization efforts. Microbial Electrolysis Cell (MECs) consist of electrochemically active bacteria where electrons (e-) extracted from organic pollutants are transferred to the positive electrode (anode) and protons (H+) are released into the aqueous environment. e- migration to the positive electrode and subsequent reaction with H+ to produce H2 has gained attention as a cleaning method. However, this process requires external energy such as direct current (DC) or alternating current AC) for the continuous production of hydrogen, and the performance of MECs has deteriorated over time due to the lack of a reliable source of energy supply, limiting its further real world application. The search for a suitable alternative to conventional power sources to reduce the input energy is promising due to its scalability and has attracted much interest from researchers all over the world.

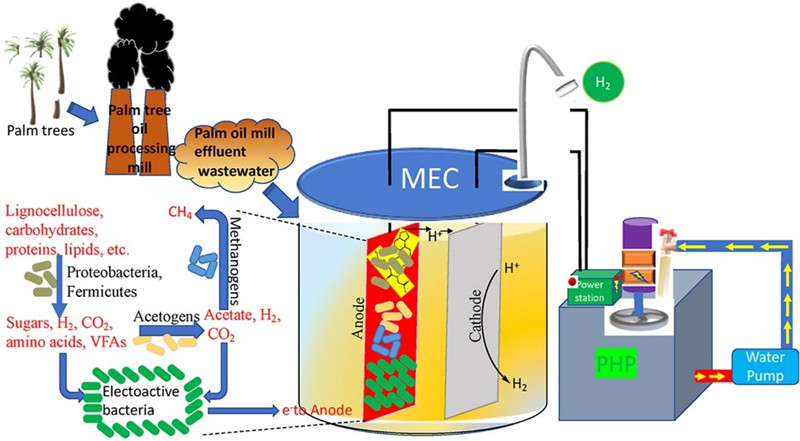

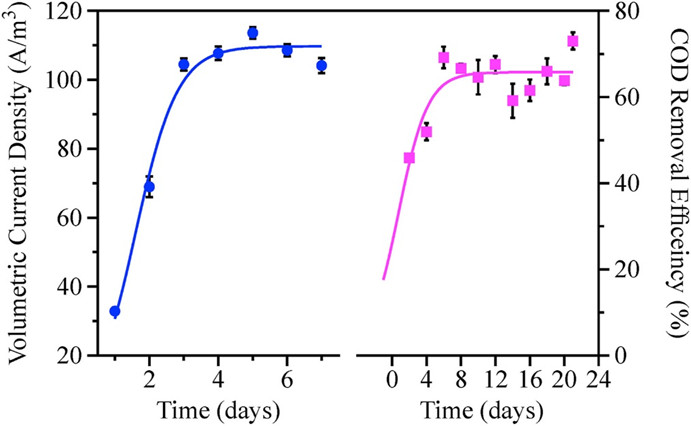

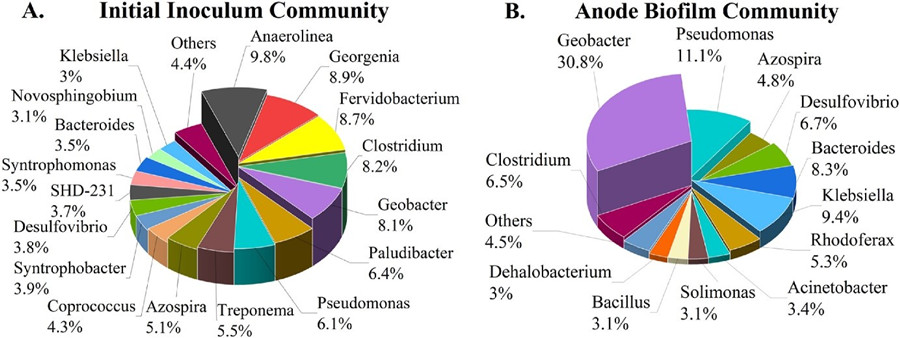

Based on this, the Separation Materials and Technology research team of Xinjiang Technical Institute of Physics and Chemistry (XTIPC) and collaborative research team from abroad has built a renewable energy generation system based on previous research to improve the energy consumption of MECs technology for treating palm oil mill wastewater (POME). To achieve renewable energy, the researchers combined Pico-hydro power generator (PHP) with single-chamber MEC reactor, which greatly increased the current density (113 A/m3) and H2 production capacity (1.16 m3 H2/m3 d) of the system, while achieving 73% organic removal from palm oil mill wastewater (POME), showing better performance than single-chamber MECs for organic removal. performance. The relatively efficient H2 recovery (r H2 = 78%) and coulometric efficiency (CE = 57%) confirmed the possibility of removing a high percentage of electrons from POME organic matter to produce >96% pure H2. the MEC nourished the POME wastewater degrading microbial community while stimulating the growth of electroactive microorganisms in the anode biofilm, which contributed to the rapid production of H2. The overall H2 recovery, COD removal and energy efficiency of PHP-MEC so far outperformed those of MECs driven by other external renewable energy sources. It has great potential for sustainable oily wastewater treatment, providing theoretical basis and technical guidance for designing effective biological strategies to recover energy from complex industrial wastewaters.

The relevant research results were published in the International Journal of Hydrogen Energy. This research work was received support from Xinjiang Technical Institute of Physics and Chemistry, Chinese Academy of Sciences (CAS), Urumqi, 830011, China, CAS Special Research Assistant Project, Project No: E15R6301. This research also funded and supported by the National University of Malaysia (UKM), Project No: DIP-2017-019 and the Malaysian Ministry of Higher Education (MOHE).

Article:https://doi.org/10.1016/j.ijhydene.2022.09.023

Fig. 1. Diagram of the experimental setup

Fig. 2. Variation of PHP-MEC reactor critical performance indicators (current density and COD removal rate) over time

Fig. 3. The genus-level categorization of microbes present in the inoculum and anodic biofilm of MEC. Genera that were <3% of the total bacterial community were denoted as “others”

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina