Research Advancements: Separation of Oil-water Emulsions by a Novel Packed Bed Electrocoagulation (EC) Process Using Anode from Recycled Aluminum Beverage Cans

Editor: | Oct 24,2022

So far, many efforts have been made to treat oily wastewater from various industries such as oil and gas, and a range of methods commonly used in the past such as gravity separation, adsorption, membrane separation, coagulation, air flotation, oxidation, biodegradation, etc., have faced several different challenges in effectively treating oily wastewater. Therefore, in recent years, more and more researchers began to pay attention to electrochemical technologies. In recent years, electrocoagulation (EC) process has been considered as a promising and sustainable treatment technology due to its simple facilities, low sludge generation, small equipment footprint and relatively low cost. It has been shown that the type of electrode material used in EC is considered as one of the key factors affecting the performance of the EC process. Therefore, material cost, energy consumption and target contaminants as well as other operating parameters must be taken into account when selecting a suitable electrode material for the treatment of oily wastewater. However, conventional electrodes (iron/aluminum plates, stainless steel plates, etc.) are not only energy intensive, but also increase the operating costs of EC processes. In the past decades, a large amount of metal scrap (metal scraps, filings, shavings, aluminum beverage cans, etc.) has been formed in production ways, which accumulates without reasonable recycling is devalued and at the same time poses a serious threat to environmental safety and human health. During recent years, the recycling of scrap for melting and recasting has not only polluted the environment, but also caused significant energy losses. In order to eliminate pollutants in an environmentally friendly manner, the use of recycled metal wastes as electrode materials in the EC process can not only reduce the process cost of it, but also reduce the corresponding energy consumption.

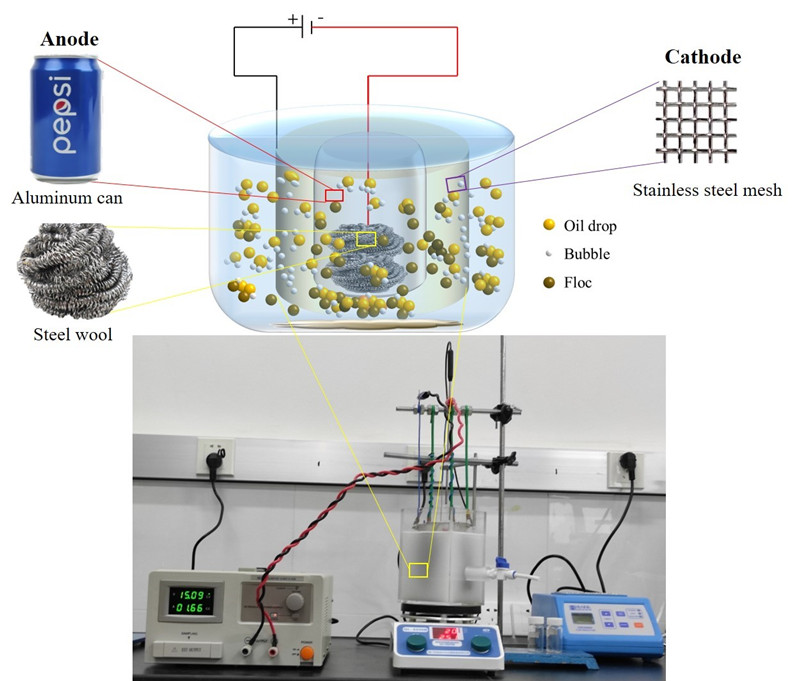

Based on this, the separation materials and technology research team of Xinjiang Technical Institute of Physics and Chemistry (XTIPC), A novel, inexpensive electrode was developed using recycled aluminum cans to replace conventional plate or tube electrodes for the separation of oil-in-water emulsions in an EC process. It has effectively solved a practical problem that the electrode consumption is fast in the process of using the electrode, which leads to high operating cost. In this work, the researchers filled recycled aluminum beverage cans with steel wool as the anode and cylindrical shape stainless steel mesh (304) as the cathode; used a Box-Behnken Design (BBD) model based on the response surface methodology (RSM), they investigated the effect of important parameters in the electrochemical process (e.g., voltage, EC time, stirring rate, and NaCl concentration).The results of the RSM showed that the COD removal rate could be as 93.53% under the optimal conditions of voltage (15 V), EC time (10 mins), stirring rate (250 rpm) and NaCl concentration (1 g/L). In addition, energy consumption analysis was performed and the process achieved a low energy consumption of 0.160 kwh/kg COD. The flocs generated by the anode and EC processes were also characterized with the help of ATR-FTIR spectroscopy, scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDS) and X-ray diffractometer (XRD) analysis after the reaction under optimal conditions. The results showed that the sludge formed in the EC reactor contained sodium chloride and hydroxide polymers with significant roughness and rich network structure, which facilitated the adsorption capacity of the flocs to the contaminants. This study reports for the first time the feasibility of recycled aluminum cans-steel wool combination electrodes (anode) for the treatment of oily wastewater by the EC process, which will contribute to the industrial application of EC technology, urban green development, and sustainable management and reutilization of waste and wastewater.

The relevant research results were published in the highly reputed journal Journal of Cleaner Production. This research work was received support from Xinjiang Technical Institute of Physics and Chemistry, Chinese Academy of Sciences (CAS), Urumqi, 830011, China, CAS Special Research Assistant Project, Project No: E15R6301. This research also funded and supported by Shanghai Cooperation Organization (SCO) Science and Technology Partnership Program and the International Science and Technology Cooperation Program [Grant number: 2022E01015].

Article:https://doi.org/10.1016/j.jclepro.2022.134693

Schematic diagram and photo of the experiment assembly setup of EC process

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina