An electrocoagulation (EC) process with a novel edge insulated electrode for separation of oil-in-water emulsions

Editor: | Apr 28,2023

Nowadays, a large amount of oily wastewater is produced by various production industries and people's daily life. These oily wastewaters cause many adverse effects on the natural environment and serious health problems to humans and animals due to their complex chemical composition and high toxicity. Therefore, there is an urgent demand to develop an oil-water separation method with high separation efficiency, low operating cost and environmental friendliness to remove the contained amount from wastewater. So far, the commonly used oil-water separation methods include membrane separation, adsorption, gravity separation, biological methods, etc. However, these methods have some disadvantages, such as low oil removal efficiency, poor environmental adaptability, complicated operation, time-consuming, membrane blockage or fouling, etc. In the last decade, Electrocoagulation (EC) technology has gained great attention in the treatment of oily wastewater due to high removal efficiency, simple operation, automation, zero chemical use, and environmental friendliness. However, EC still faces some major challenges in electrochemical processes, such as electrode passivation and high energy consumption, which not only reduce the removal efficiency but also increase the economic cost of the electrochemical process. Under optimized conditions, differences in electrode surface potential values (current distribution) were found due to the enhancement of the electrolyte on the electrode edge potential. This uneven current distribution of the electrode reduces the oil-water separation efficiency and increases the possibility of side reactions. Therefore, changing the distance, area and structure of electrodes is an effective way to improve the uniformity of current distribution.

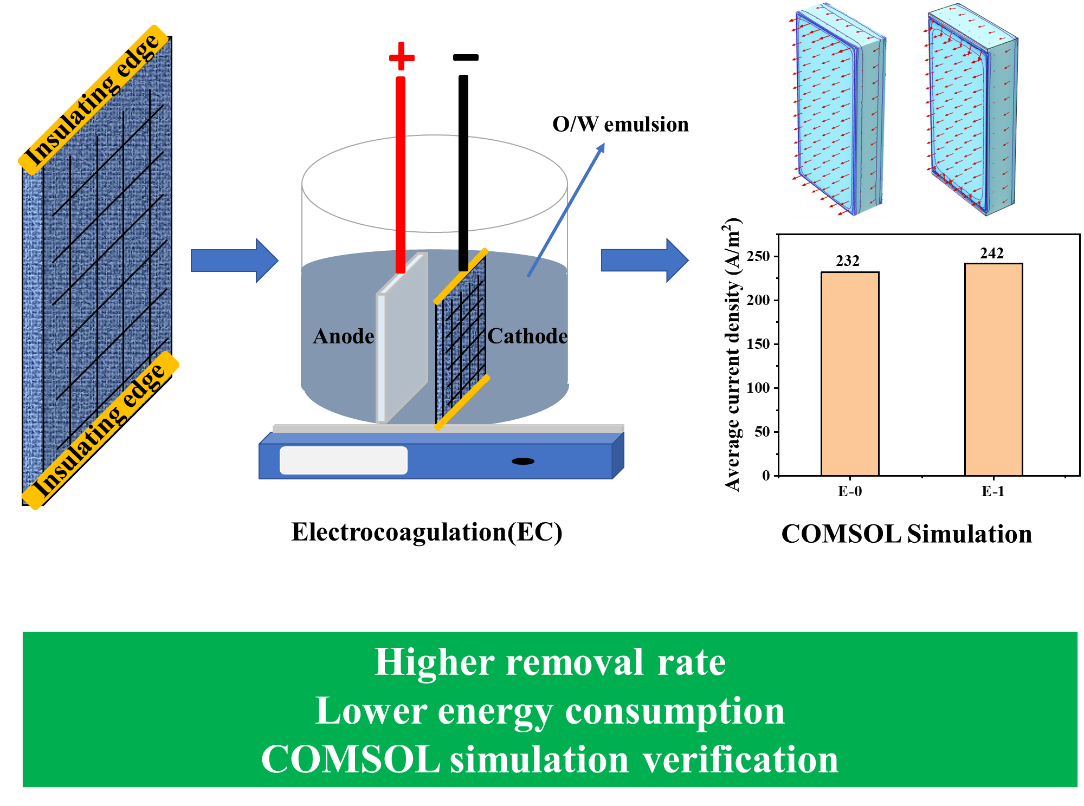

In summary, the Separation Materials and Technology Research team of Xinjiang Technical Institute of Physics and Chemistry (XTIPC), Chinese Academy of Sciences (CAS), used epoxy resin with insulating properties to coat the upper and lower edges of SS mesh electrodes to obtain edge-insulated electrodes to improve the current density and the uniformity of current distribution. Subsequently, the effect of current distribution on the oil-water separation performance was measured and analyzed using two combined electrodes. The currents were recorded during the EC to calculate the energy consumption. The results showed that the electrode and energy consumption of the control E-0 were 0.81 kg/m3 and 1.95 kWh/kg, respectively, compared to the electrode and energy consumption of E-1 with edge-insulated structure, which were 0.69 kg/m3 and 1.19 kWh/kg, respectively, indicating that the edge-insulated electrode consumed less energy. The COD values of the emulsified oil before and after the reaction were measured using a COD multi-parameter spectrophotometer and a COD dissipation reactor, and the COD removal rates of the EC process with different combinations of electrodes were calculated. The results showed that the COD removal rate of E-1 (93.73%) was slightly higher than that of E-0 (92.44%) without the edge-insulated structure. The researchers also modeled the potential distribution and current distribution of the edge-insulated structure electrode using COMSOL software, and the combination of theoretical calculations and experimental validation of oil-water separation revealed the mechanism of the edge-insulated electrode material to improve the oil-water separation performance of the EC process. Overall, this new edge-insulated electrode material points to a new direction for optimizing oil removal efficiency and energy consumption.

The research results were recently published in the international Journal《Case Studies in Chemical and Environmental Engineering》. The research work was supported by the Natural Science Foundation of Xinjiang Uygur Autonomous Region, the Tianqi Doctoral Program of Xinjiang Uygur Autonomous Region, the Outstanding Youth Fund of Xinjiang Uygur Autonomous Region, the Shanghai Cooperation Organization Science and Technology Partnership Program and the International Science and Technology Cooperation Program.

Fig.1: Illustration of EC experimental set-up used in this study

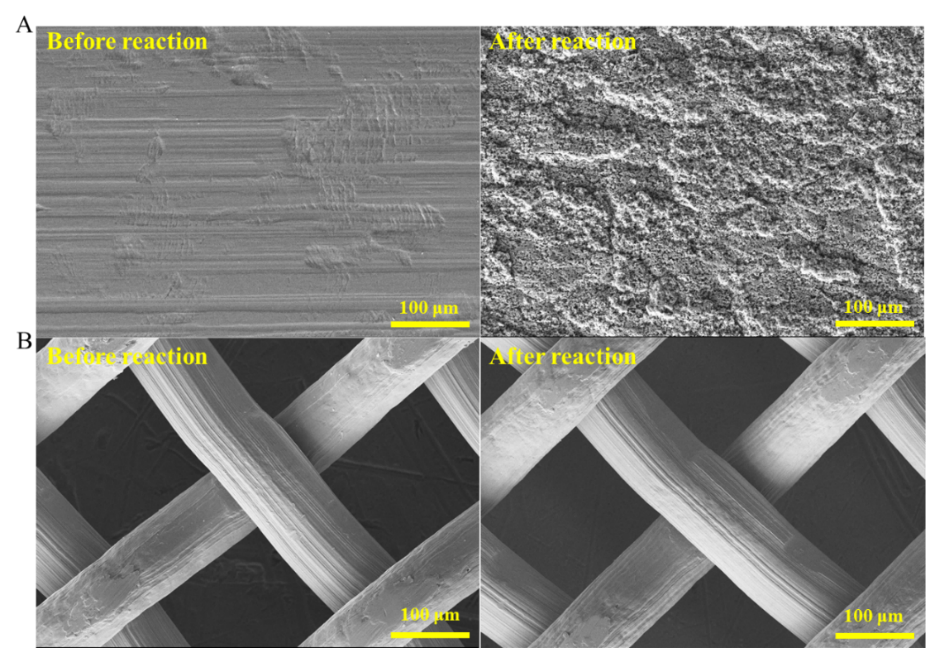

Fig. 2: SEM images of electrode materials(A): Al plate -anode; (B): SS mesh-cathode.

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina