Research Progress: Sono-alternating current-electro-Fenton process for the removal of color, COD from distillery industrial wastewater

Editor: | Jun 02,2023

Nowadays, large amount of industrial wastewater is produced by distilleries. It contains high and medium concentration of organic pollutants, with high concentration of chemical oxygen demand (COD), large BOD/COD value, seasonal output and other characteristics. It is one of the most difficult to treat industrial wastewater in the global brewing industry. Therefore, more efficient and practical advanced treatment techniques are required to reduce the negative environmental effects and potential risks associated with distillery industrial wastewater (DIW) discharges. These technologies must also be able to meet current regulatory standards. For the deterioration of DIW, several remediation approaches have been investigated, such as, microalgae, photo (UV)/hydrogen-peroxide (H2O2), integrated aerobic biological oxidation and ozonation (O3), Microbial Fuel Cell (MFC), photo-catalytic degradation, ultrasound (US) and enzyme, adsorptive treatment, electrochemical (EC) process and others. Advanced Oxidation Processes (AOPs) have obtained the greatest attention for organic waste removal from wastewaters since they have a high organic load in terms of COD and a low five days-biochemical oxygen demand (BOD5). However, for many AOPs associated processes, including photo-catalyst and Fenton (Fe2+/H2O2), Photo-Fenton (UV/Fe2+/H2O2), and Fenton-like AOPs, pre-and post-treatment of wastewater is required, which includes controlling the pH, separating the wastewater, forming sludge, regeneration of the catalyst, and activation etc.

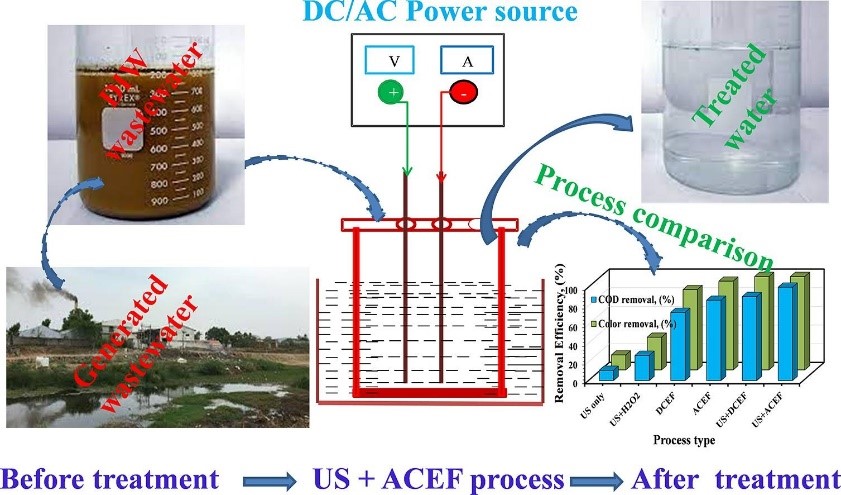

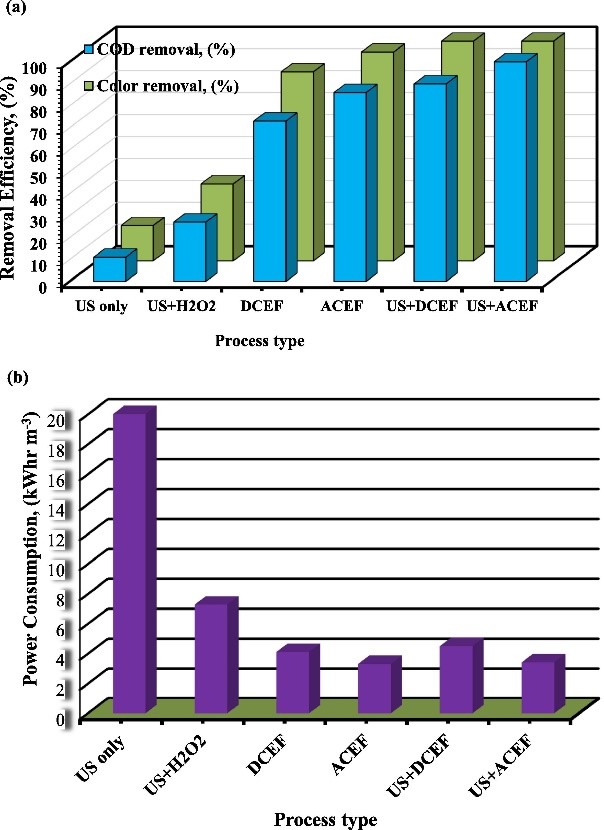

Based on this, Separation Materials and Technology research team of Xinjiang Technical Institute of Physics and Chemistry (XTIPC), Chinese Academy of Sciences (CAS), and collaborative research team from Jimma University in Ethiopia have developed an integrated process which have a unique synergism effect on treatment efficiency. Based on the reviewed literature, the current study compared the effectiveness of color and COD removal with power consumption from DIW using US alone, US + H2O2, DCEF, ACEF, US + DCEF, and US + ACEF. Furthermore, to increase the color and COD removal efficiency with the least amount of power consumption, key operational parameters including sonication power (P), COD, initial pH, H2O2 concentration, inter-electrode distance (IED), current density (CD), pulse duty cycle (PDC), combination of electrode (CE) and treatment time (RT) have been studied. It has been demonstrated that the US + ACEF method is a more effective treatment technique for the removal of pollutants from distillery industrial wastewater than the US only, US + H2O2, DCEF, ACEF, and US + DCEF process. Moreover, according to experimental findings, using the US + ACEF process with operating parameters: P =100W, COD = 3000 mg/L, pH = 3, H2O2 = 250 mg/L, IED =1 cm, CD = 0.40Adm?2, PDC = 0.50, CE-Fe/Fe, and RT =180 min achieved highest level of color (100%) and COD (100%) elimination with lower power consumption of 3.4 kWhr m?3. The treated distillery industrial wastewater was tested in accordance with local public health reuse regulations, and the findings revealed that the treated water is safe for public and environmental health.

To sum up, the sono-electrochemical (US-EC) process is able to overcome the constraints of electrode passivation and electrode fouling, as well as boost both the rate of mass transfer and the rate of pollutants defecation. During the process of degrading persistent organic pollutants (POPs), the US-EC approach speeds up the reaction rate while also extending the life of the electrodes, improving mineralization efficiency, and allowing for in-situ cleaning of the electrode surfaces. When compared to conventional wastewater treatment methods, the newly developed US + ACEF approach could be considered a more technologically sophisticated and economically option for the elimination of contaminants from wastewater and industrial effluents.

This research progress was published in《Separation and Purification Technology》 journal entitled as “Sono-alternating current-electro-Fenton process for the removal of color, COD and determination of power consumption from distillery industrial wastewater”(Sep Purif Technol, 2023, 319, 124031). The research work was supported by the Tianchi Doctor Program of Xinjiang Uygur Autonomous Region, and the Natural Science Foundation of Xinjiang Uygur Autonomous Region.

Fig.1: Illustration of experimental set-up used in this study

Fig. 2: Comparative analysis of different methods (US: Sonolysis, US + H2O2: Sono-Hydrogen peroxide (H2O2), DCEF: Direct Current-Electro-Fenton, ACEF: Alternating Current-Electro–Fenton, US + DCEF: Sono-Direct Current-Electro-Fenton, US + ACEF: Sono-Alternating Current-Electro-Fenton)

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina