Research Progress: Industrial wastewater treatment using batch electrocoagulation (BRE) process: Studies on operating parameters

Editor: | Aug 17,2023

In recent years, electrocoagulation (EC) technologies has garnered recognition as a water and wastewater treatment method that is both effective and environmentally friendly, and it is able to remove a wide variety of contaminants. Most EC research has so far been done in batch reactors that are small enough to operate in laboratories to wastewater treatment. This is due to the ease with which these reactors can be installed and operated. The benefits and capabilities of coagulation, flotation, and adsorption, in addition to electrochemistry, are included into the EC process. As a consequence of this, it provides a number of benefits that are not available with the more traditional approaches to treatment, and it is distinguished from other approaches by its eco-friendliness, simplicity of operation, adaptability, compactness, and low chemical demand. However, The EC method is plagued by excessive energy and electrode consumption, in addition to electrode passivation. Thus, the batch-electrocoagulation method showed worse outcomes in terms of pollutant removal, performance with high energy consumption, and operating costs, the process was denied.

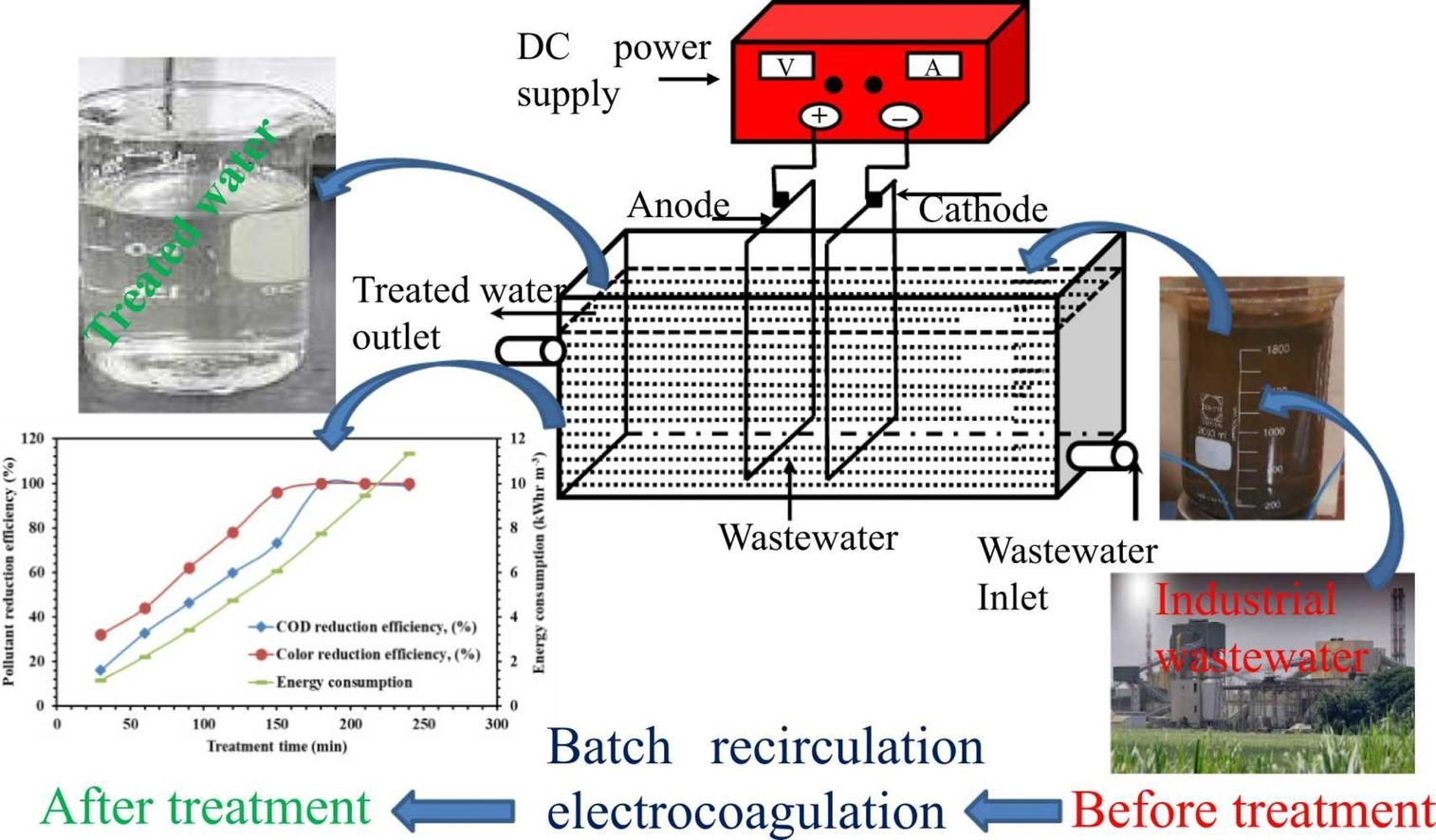

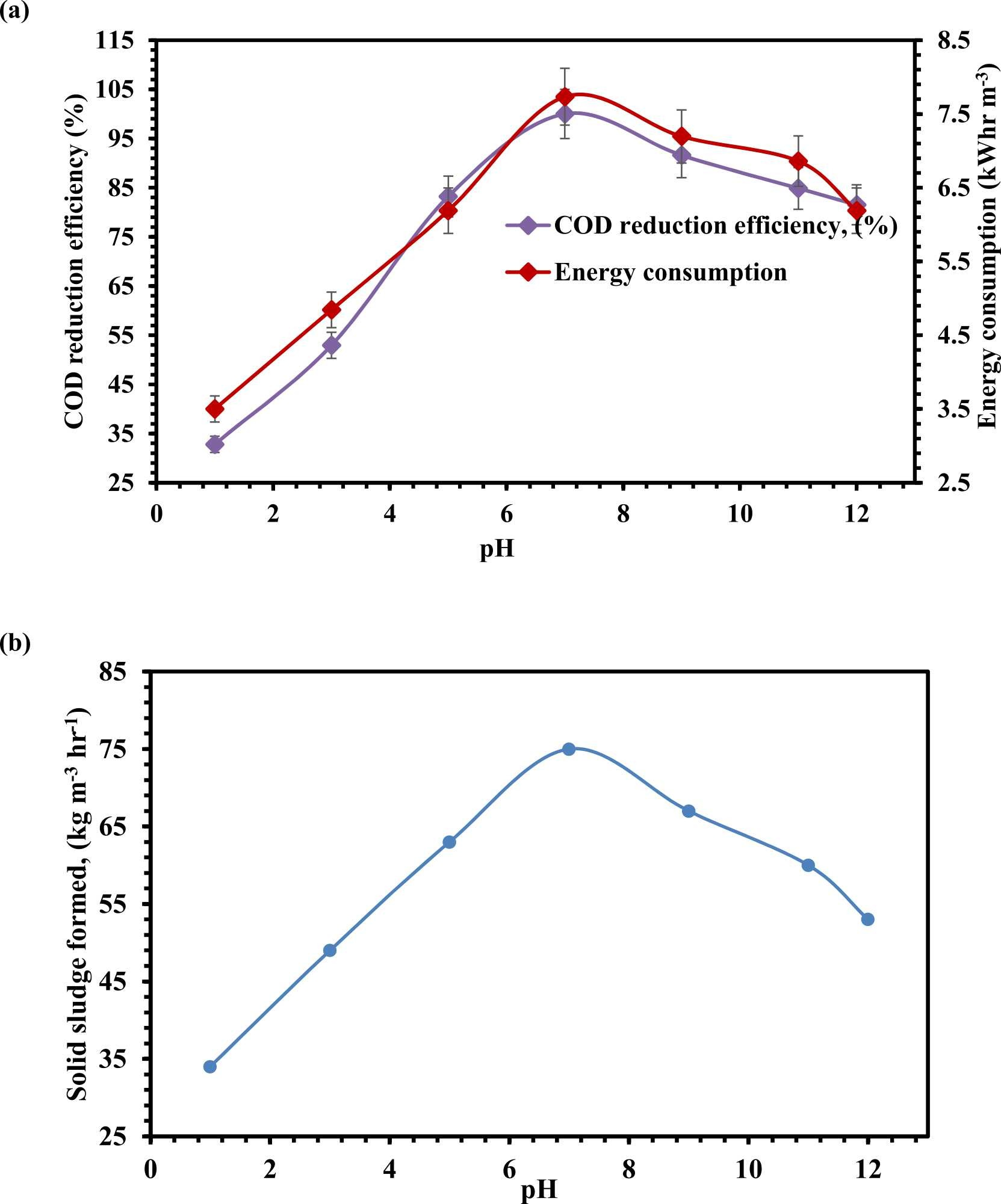

Based this, Separation Materials and Technology research team of Xinjiang Technical Institute of Physics and Chemistry (XTIPC), Chinese Academy of Sciences (CAS), and collaborative research team from Jimma University in Ethiopia, proposed the intermittent reflux electric flocculation process (BRE) to solve the problems of large energy consumption and low pollutant removal rate. Based on the reviewed literature, the impact of different operational parameters, including COD, wastewater pH, cur-rent, inter-electrode spacing, combination of electrodes, recirculation flow rate, concentration of electrolytes, and treatment duration on color (%), COD reduction efficiency (%), and energy consumption was examined. According to experimental findings, the color removal was 100 %, COD removal was 99.90 %, and energy consumption was 7.73 kWh/m3 for COD of 3600 mg/L, current of 0.56 Amp, combination of electrodes of Fe/Fe, inter-electrode spacing of 1 cm, wastewater pH of 7, flow rate of 15 L/h, concentration of electrolytes of 5 g L?1, and treatment time of 180 min, respectively. It was found that, a longer treatment period, higher electrolyte concentrations and current, lower COD concentrations and recirculation flow rates, Fe/Fe electrode pairings, a pH of 7, and a smaller inter-electrode spacing all contributed to increased COD reduction efficiency (%). The quantity of solid sludge formed were studied with the help of operational parameters, and the results were reported. Under the optimized process conditions, the wastewater treated can be fully recovered as clean water.

To sum up, the continuous electrocoagulation method can reduce color, COD, TOC, TS, and turbidity in wastewater, and reduce the electrical energy consumption. As a consequence of this, the results of the experiments have shown that the batch recirculation electrocoagulation process has the potential to be a more promising solution to the problem of eliminating contaminants from wastewater and industrial effluent.

This research progress was published in《Sustainable Chemistry for the Environment》 journal entitled as “Industrial wastewater treatment using batch recirculation electrocoagulation (BRE) process: Studies on operating parameters”(Sustainable Chemistry for the Environment, 2023, 2, 100014). The research work was supported by the Tianchi Doctor Program of Xinjiang Uygur Autonomous Region, and the Natural Science Foundation of Xinjiang Uygur Autonomous Region.

Fig.1: Illustration of experimental set-up

Fig. 2. Effect of pH on (a) % COD reduction efficiency and energy consumption and (b) Solid sludge formed by using BRE process (Experimental conditions: COD - 3600?mg/L; current - 0.56 Amp; inter-electrode spacing - 1?cm; combination of electrodes - Fe/Fe; recirculation flow rate - 15?L/h; concentration of electrolytes - 5?g/L, and treatment time - 180?min).

Fig. 2. Effect of pH on (a) % COD reduction efficiency and energy consumption and (b) Solid sludge formed by using BRE process (Experimental conditions: COD - 3600?mg/L; current - 0.56 Amp; inter-electrode spacing - 1?cm; combination of electrodes - Fe/Fe; recirculation flow rate - 15?L/h; concentration of electrolytes - 5?g/L, and treatment time - 180?min).

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina