Research progress in anti-corrosion mechanism of basalt fiber in seawater

Editor: | Apr 20,2024

Basalt fiber-reinforced composites can be applied in marine engineering. However, the property of composite materials tends to reduce when exposed to complex oceanic environments such as high temperature and humidity. Currently, studies mainly have focused on the degradation of basalt fiber-reinforced composites in seawater. Although the matrix in the composite can somehow protect the basalt fiber (BF), chloride ions and water molecules in seawater can still diffuse to the fiber surface and subsequently corrode the fiber, ultimately leading to the failure of the composite. There is no universal understanding of the effect of structure changes of BF surface on tensile strength after seawater corrosion.

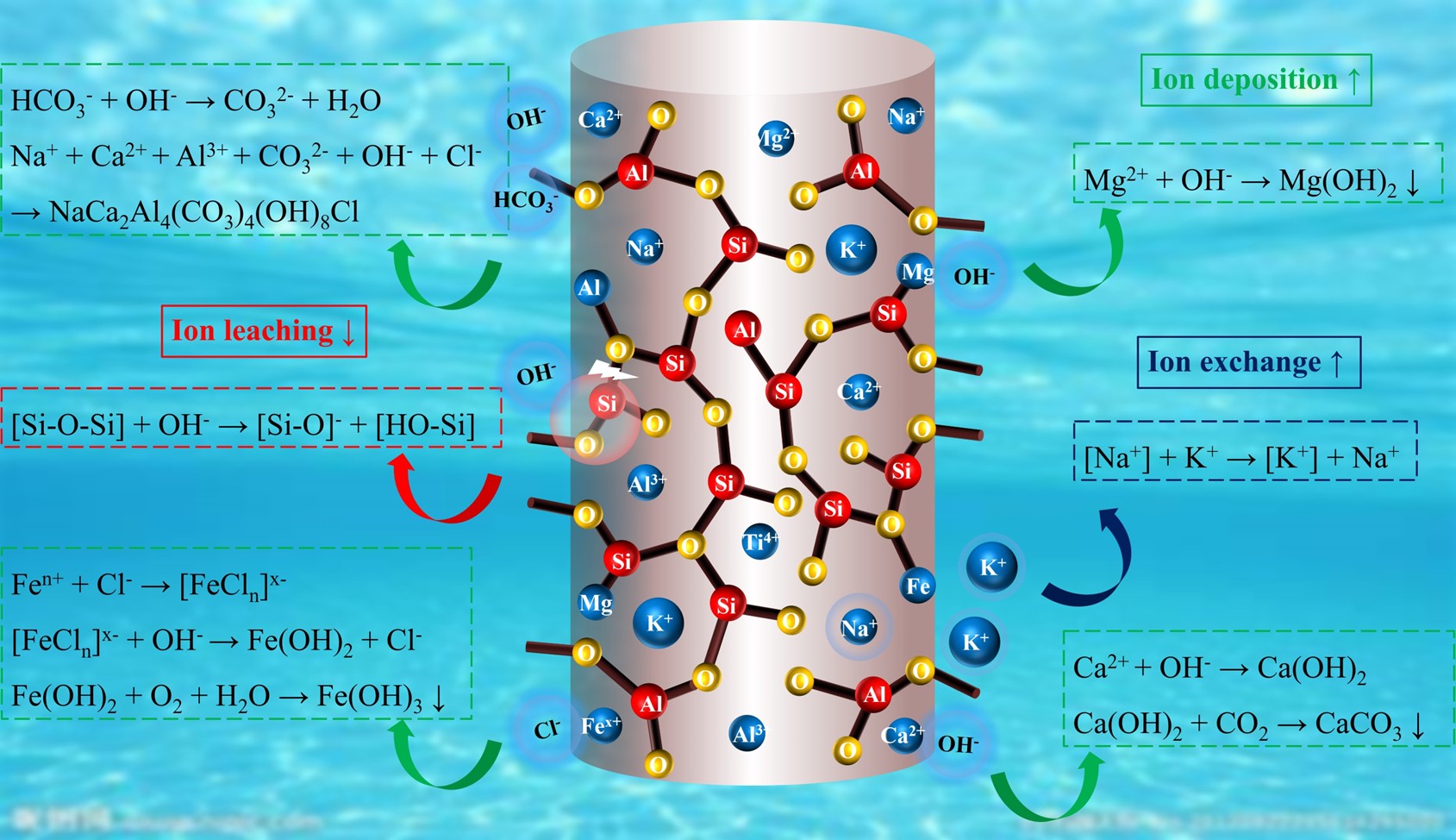

Recently, Peng-Cheng Ma’s group in the Xinjiang Technical Institute of Physics and Chemistry, and Molong Duan’s group from the Hong Kong University of Science and Technology, studied the mechanical and morphological variations of BF in seawater. The effects of corrosion temperature and time on the tensile strength of commercial BF were investigated. The results showed that the mechanical properties of BF first increased and then decreased. With the aggravation of seawater corrosion, surface morphologies of BF varied from a smooth surface, then rougher surface, and finally to the particles and plate-like particles, such as Mg(OH)2, NaCa2Al4(CO3)4(OH)8Cl. Based on the above results, the corrosion mechanism of BF in seawater was proposed (Fig. 1). The Na+ in the fiber could be replaced by K+ in seawater, and the compressive stress generated by the invasion ions was able to enhance the strength of fiber. As the Si-O-Si structure in fiber was attacked by OH- in seawater, some metal ions (Such as Mg2+) leached, forming a corrosive layer made of insoluble hydroxide on the fiber surface. The overall BF corrosion in seawater could be described as a dynamic process with competitive reactions, along with variations in the strength of fiber due to the ion exchange, ion leaching, and insoluble precipitation on the fiber surface.

Therefore, nanocomposite sizing was coated on the BF surface to improve the mechanical and seawater corrosion-resistant properties. The as-synthesized polysilsesquioxane nanosheets were added into the sizing, and the strength of BF was significantly enhanced, since nanosheets not only filled the voids in the coating layer but also transferred the loaded stress to the fiber. The results indicated that the ion permeation was largely restrained for BF with nanocomposite sizing since the ions were forced to travel through tortuous and longer paths owing to the existence of nanosheets, which significantly kept the fiber from environmental attacks (Fig. 2). Therefore, the Si-based nanosheets could work as an effective sacrificial layer to prevent fiber from being attacked by the OH- ions in seawater.

The research work was supported by the project of Tianshan Talents Program in Xinjiang and Talents Program of Chinese Academy of Sciences. The research results were published in Construction and Building Materials.

Fig. 1 Schematic illustration showing the corrosion mechanism of BF in seawater

Fig. 2 Schematic showing the corrosion behaviors of BF coated with different sizing

Article:

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina