A New Thermosensitive Ceramics With Sensing Limit Up To 1600℃

Editor: | Aug 21,2024

With the development of aero-engines towards high connotation ratios, high thrust-to-weight ratios, and high turbine inlet temperatures, the working temperature of engine hot-end components is increasing. Rapid monitoring and timely warning of the temperature for the engine's hot end components are indispensable technical assurances for fabricating high-performance engines. Therefore, developing high-temperature temperature sensors with high performance is of great significance for promoting the development of the aviation industry.

Compared to traditional platinum resistors and thermocouples, low-cost, small size, and fast response negative temperature coefficient (NTC) thermistors are considered the ideal choice for the next generation of advanced high-temperature temperature sensors.

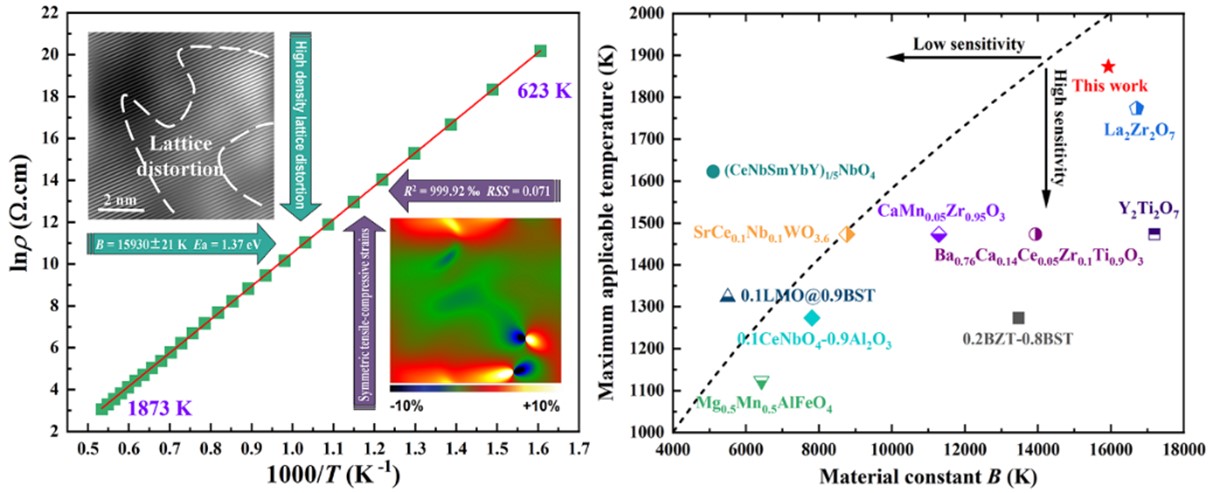

Recently, researchers in Xinjiang Technical Institute of Physics and Chemistry of Chinese Academy of Sciences designed and synthesized Ln3NbO7 (where Ln=Dy Lu) based high-temperature thermosensitive ceramics with high ceiling temperature and high-temperature stability through a high entropy strategy, aiming at solving the problems of low ceiling temperature and poor high-temperature of thermosensitive ceramics. The mechanism of lattice distortion on the tilt of NbO6 octahedral and dipolar interactions of the off-centered Nb cations was elucidated, and the influence of configuration entropy and size disorder on ceramic microstructure was revealed. A customized high-density symmetric tensile compression strain solved the stability degradation caused by the tilt of NbO6 octahedral and dipolar interactions of the off-centered Nb cations. The prepared (Ho0.2Er0.2Tm0.2Yb0.2Lu0.2)3NbO7 ceramic not only has the highest ceiling temperature close to the theoretical limit and a wide temperature range (350-1600 ℃) but also maintains excellent sensitivity and long-term high-temperature stability (resistance drift rate is less than 1% after 400 hours of aging at 1600 ℃). It provides a new idea for designing high-temperature thermosensitive ceramics with high ceiling temperatures and good high-temperature stability.

Figure. Microstructure and Properties of (Ho0.2Er0.2Tm0.2Yb0.2Lu0.2)3NbO7 Ceramic

The related achievement has been published in Journal of Materials Chemistry A (J. Mater. Chem. A. 2024,12,21085-21094). This research was supported by the Youth Innovation Promotion Association of the Chinese Academy of Sciences, the Xinjiang Tianshan Talent Training Program, the West Light Foundation of the Chinese Academy of Sciences, etc.

Article link:https://doi.org/10.1039/D4TA03260H

Contact:

Bo Zhang

State Key Laboratory of Functional Materials and Devices for Special Environmental Conditions, Xinjiang Key Laboratory of Electronic Information Materials and Devices, Xinjiang Technical Institute of Physics & Chemistry of CAS, Urumqi, China

E-mail: zhangbocas@ms.xjb.ac.cn

Key words:

High-entropy ceramics; Microstructure; High-density lattice distortion; High-temperature thermosensitive ceramics

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina