Research Progress in Multifunctional Graphene Oxide-Based Nanocomposite Materials and Its Application Emerging Contaminants Treatment

Editor: | Sep 06,2024

In recent years, the demand for functional textiles in scientific and industrial applications has shown a clear upward trend. Surface functionalization of traditional fabrics has become a key method for imparting new functional properties. PET (polyethylene terephthalate) fabrics, a common polymer material in textile engineering, are favored for their excellent mechanical strength, wrinkle resistance, and durability. However, the inherent hydrophobicity, low moisture absorption, and tendency to generate static electricity in PET fabrics limit their further application in harsh environments such as organic pollution and high-temperature drying. To overcome these limitations, a series of specific surface modification techniques have emerged. Methods such as plasma treatment, coating, or chemical grafting can significantly enhance the hydrophilicity, antibacterial properties, and UV resistance of PET fabrics, broadening their application prospects in fields such as healthcare, electronics, and environmental protection. Therefore, customizable surface modification of PET fabrics has become a necessary strategy to enhance their functionality and lays the foundation for developing a new generation of high-performance smart textiles.

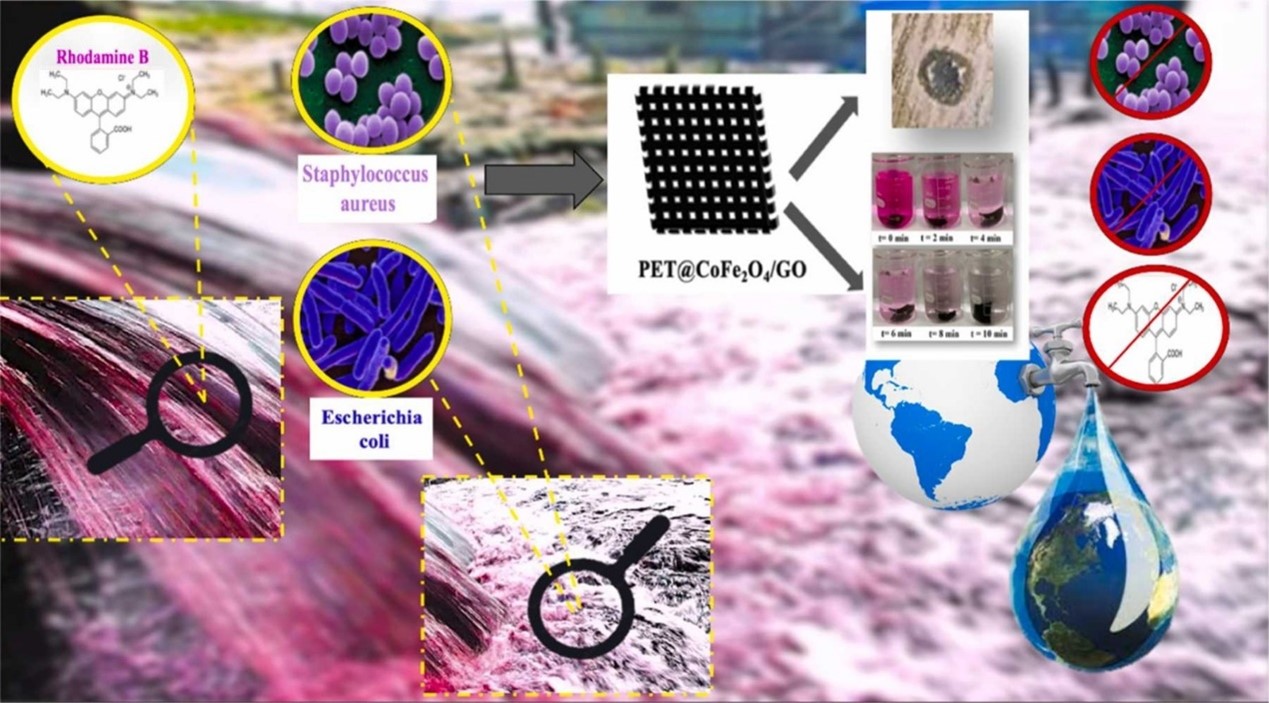

Recently, Separation Materials and Technology research team of Xinjiang Technical Institute of Physics and Chemistry (XTIPC), Chinese Academy of Sciences (CAS), and collaborative research team from Hassan II University of Casablanca in Morocco, successfully synthesized a PET fabric-based catalyst with exceptional thermal stability, mechanical properties, and catalytic activity. This was achieved using natural graphite, rhodamine B (C28H31CIN2O), potassium peroxymonosulfate (KHSO5), cobalt chloride hexahydrate (CoCl2·6H2O), iron chloride hexahydrate (FeCl3·6H2O), and PET fabrics. The catalyst was applied to the stable catalytic continuous degradation reaction. The results showed that the newly developed PET/CoFe₂O₄/GO composite fabric exhibited excellent antibacterial activity and chemical stability, supporting multiple reuses. Furthermore, without altering the original crystallinity or fiber quality of the PET fabric, the CoFe₂O₄/GO coating formed a strong interface with the PET fabric substrate, enhancing its inherent mechanical strength. Remarkably, after just 12 minutes of the catalytic degradation reaction, the total organic carbon (TOC) removal rate reached 89.82%, and after seven degradation cycles, it maintained an effective degradation rate of over 60%, with an antibacterial zone diameter of up to 13 mm. These findings demonstrate the advantages of the PET/CoFe₂O₄/GO composite fabric. This work provides a simple, practical, and efficient method for preparing a novel PET fabric-based catalyst with great potential in medicine, heterogeneous catalysis, and wastewater treatment.

The research results were recently published in the international journal in Colloids and Surfaces A: Physicochemical and Engineering Aspects entitled as Strategically engineered multifunctional graphene oxide hybrid nanomaterials for efficient catalytic degradation and emerging contaminants treatment (Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2024, 703, 135207). The first author of the study is Dr. Ghizlane Achagri, she is a postdoctoral researcher from the Separation Materials and Technology Group of the Xinjiang Institute of Physics and Chemistry, Chinese Academy of Sciences, and the corresponding author is Prof. Abudukeremu Kadier. This work was supported by the Tianchi Doctor Program of Xinjiang Uygur Autonomous Region, and the National Foreign Young Talents Program- Department of Foreign Expert Services of the Ministry of Science and Technology, China.

Article:https://doi.org/10.1016/j.colsurfa.2024.135207

Fig. 1: Graphical Abstract and Research Ideas

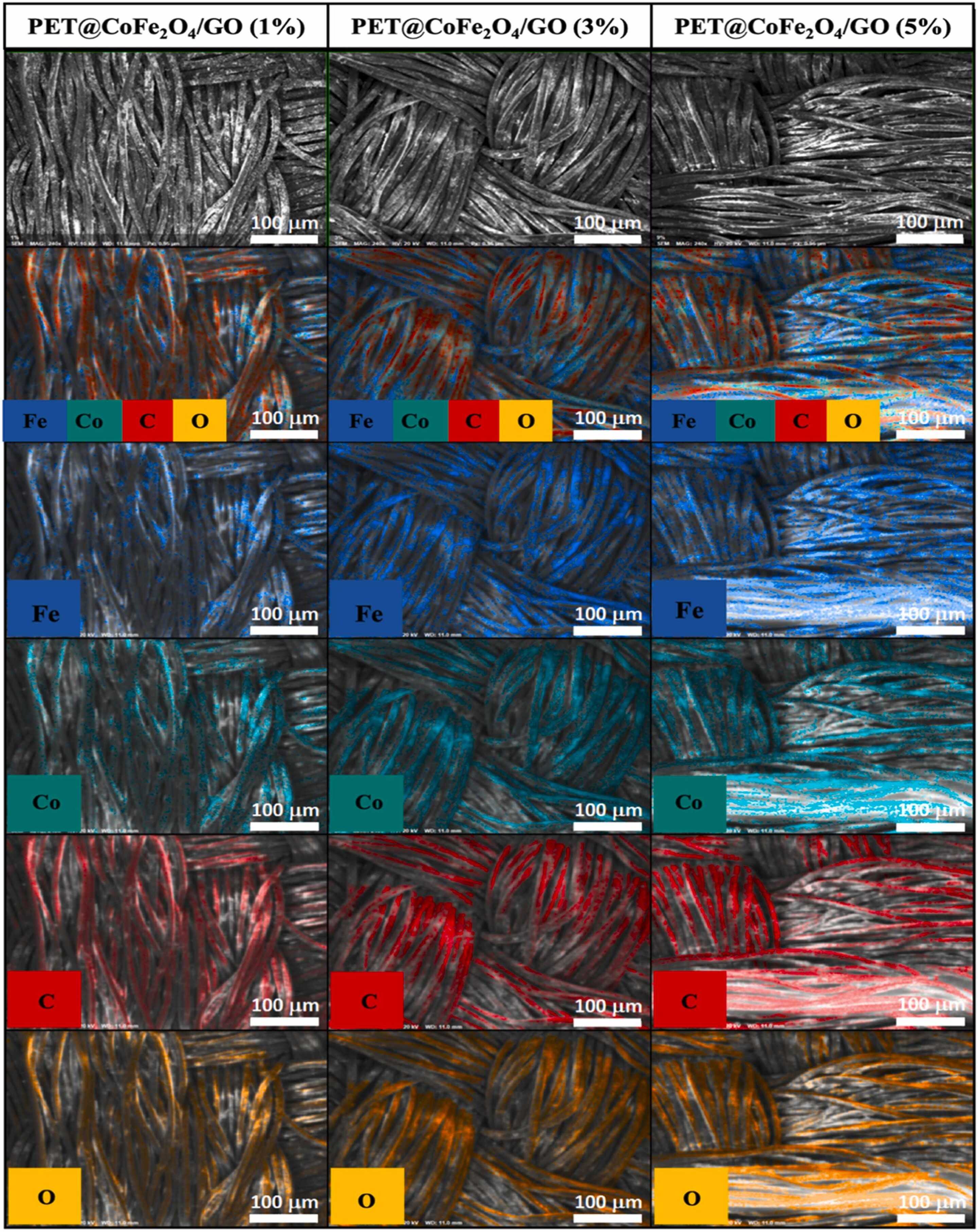

Fig. 2: X-ray mapping images of PET@CoFe2O4/GO (1 %), PET@ CoFe2O4/GO (3 %) and PET@CoFe2O4/GO (5 %) fabrics

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina