Research Progress: Melt Viscosity Prediction and Fiber Formation of Basalt Ores

Editor: | Dec 17,2024

Basalt fiber is a kind of fiber material made from the natural basalt ore as raw material by high temperature melting and filament forming. The viscosity of basalt melt is very important to control the ore melting process, determine the melting and fiber forming temperature and reduce the fiber production cost. The high-temperature viscometer is usually used to measure the viscosity of basalt melt, but it is faced with the shortcomings of complicated testing steps and time-consuming. In addition, as a natural mineral, basalt ore contains a variety of oxides and the content of these components fluctuates greatly, which brings challenge to accurately characterizing the melting behavior of basalt ores.

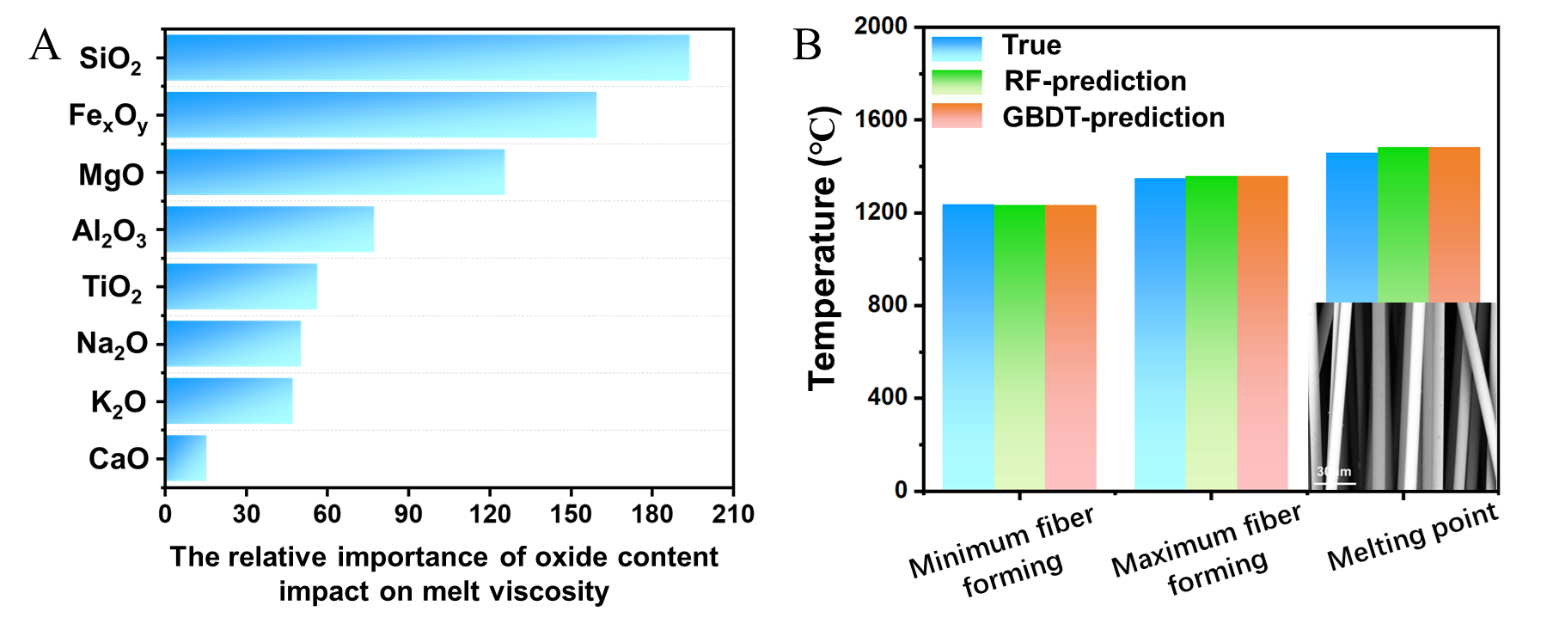

Recently, a research group from Xinjiang Technical Institute of Physics & Chemistry, Chinese Academy of Sciences, in collaboration with the Hong Kong Polytechnic University, has made progress in predicting the melt viscosity of basalt ores. Based on the group’s previous testing results and publicly reported literature’s data, the researchers constructed a dataset covering features such as basalt oxide content, temperature and melt viscosity (Includes 70 basalt ore compositions and 2849 temperature-viscosity data points). By using the data-driven artificial intelligence technology, two machine learning models, Random Forest (RF) and Gradient Boosting Decision Tree (GBDT), were applied to predict the melt viscosity of basalt ores accurately. Among them, the GBDT model performed better on the entire dataset, with a relative error of only 0.04% and an excellent coefficient of determination (A statistical indicator of the reliability of the regression model) of 0.99. Through interpretable analysis of the models, the researchers found that the composition of oxides such as silicon, iron and magnesium in basalt ores shows a particularly significant effect on the viscosity (Fig. 1A), mainly because these oxides play the role of network formers in the network structure of basalt melt, and thus affect the flow characteristics of the melt.

Based on the established viscosity-temperature relationship, the researchers successfully predicted the key temperature parameters for the basalt melting and fiber formation, including melting point, minimum and maximum fiber forming temperature. Compared with the true testing data, the predicted errors of the above parameters were all within 2% (Fig. 1B). Under the guidance, the researchers used a variety of basalt ores from the Eastern Tianshan Mountains as raw materials to successfully prepare the basalt fibers with controllable diameter and strength (Embedded image in Fig. 1B), in which the tensile strength of the monofilament can reach up to 2061MPa, which can be used as the reinforcement materials for the preparation of fan blades, photovoltaic supports, etc.

This research provides a theoretical basis for the melting process of high- performance basalt fiber, and also provides technical support for the deep development and application of basalt resources. At present, the research team is cooperating with local enterprises in Xinjiang to build a production line of basalt fiber with an annual output of 20,000 tons.

The above research was recently published in the Journal of Non-Crystalline Solids, and this work was supported by the “Tianchi Talents” and “Tianshan Talents” introduction programs in Xinjiang and the “West Light” program of the Chinese Academy of Sciences.

Article link: https://doi.org/10.1016/j.jnoncrysol.2024.123302

Fig. 1 Data-driven high-temperature viscosity prediction of basalt ores (A: The relative importance of oxide composition in influencing melt viscosity of basalt ores; B: Comparison between the predicted and measured results of the characteristic temperature for melting and fiber formation, the embedded image is the scanning electron microscope photo of the obtained basalt fiber).

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina