Progress in the Research of Producing H2-rich Syngas from Biomass Gasification

Editor: YIN Jiao | Jan 23,2025

The focus on hydrogen production from biomass is growing, with thermochemical methods being the predominant approach. Among these methods, steam gasification has emerged as a particularly promising technique for producing H2-rich syngas. However, the gasification process often leads to the generation of substantial tar, which can potentially cause corrosion of equipment and clogging of pipelines, thereby reducing the overall efficiency of the process. The addition of catalysts to the gasification process has been shown to be an effective means of promoting tar cracking and increasing H2 production. Additionally, inorganic minerals inherent in biomass, such as the abundance of alkali/alkaline earth metals (AAEMs), have been observed to promote the production of H2-rich syngas from biomass during the gasification reaction. However, further elucidation is required to elucidate the effect of AAEMs on gas production and the mechanism of the interactions between the different metals.

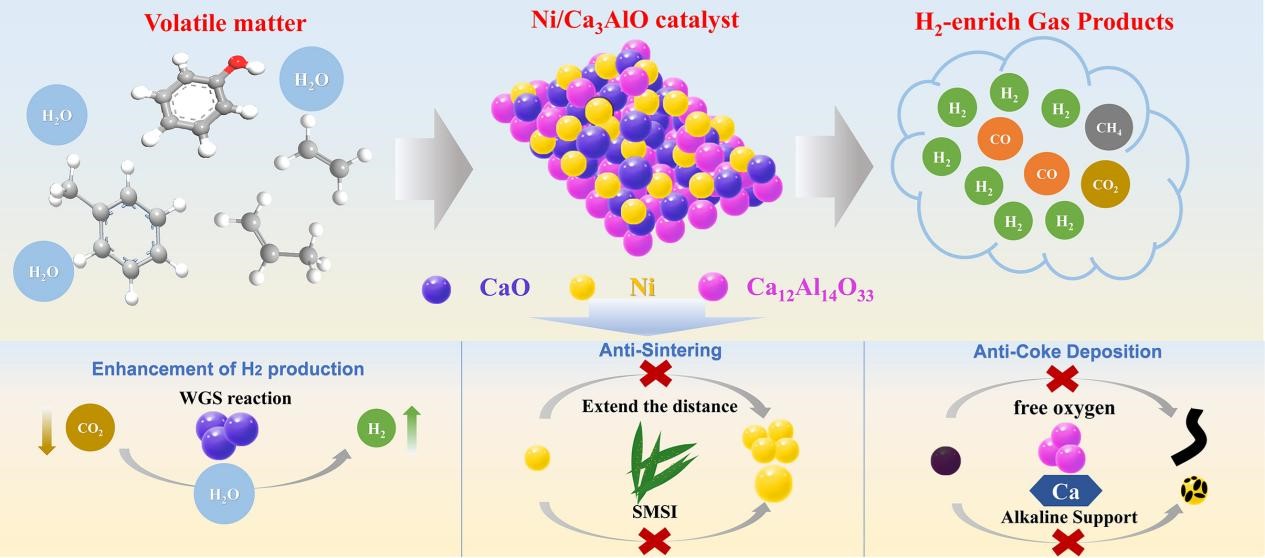

Recently, the research team led by Yin Jiao from the Xinjiang Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, has successfully designed a series of Ni/CaO-Ca12Al14O33 catalysts. The research team has made progress in enhancing the stability of these catalysts. The experimental findings demonstrated that the Ni/Ca3AlO catalyst exhibited excellent catalytic performance and remarkable cyclic stability. The yield and concentration of hydrogen in syngas were determined to be 30.08 mmol/gbiomass and 60.61 vol% for the initial reaction. It was observed that a minimal amount of carbon deposition and slight sintering occurred on the surface of the catalyst after 10 cycles. The excellent anti-sintering performance of the catalyst was primarily attributed to its unique blade-like morphology, which effectively facilitated metal-carrier interactions, thereby hindering Oswald ripening. The anti-carbon accumulation performance was primarily attributed to the inhibition of filamentary carbon formation by Ca12Al14O33 within the carriers, as well as the suppression of encapsulated carbon precursors by Ca doping. This work provides a theoretical basis for the design of novel nickel-based catalysts and their application in hydrogen production from biomass catalytic gasification.

The work has been published in full in journal Energy, with a title of "A highly stable leaf-like Ni/Ca3AlO catalyst for hydrogen production from biomass gasification".

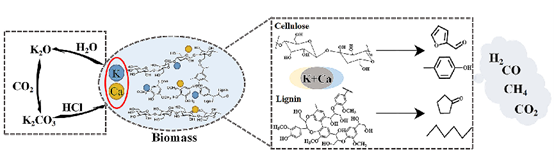

Furthermore, the researchers investigated the effects of AAEMs on the production of each gas component and the mechanisms of intrinsic metals K and Ca on the production of H2-rich syngas using three typical biomasses and their semicokes in Xinjiang. The investigation revealed that the H2 and syngas yields from cotton stalk gasification reached up to 29.4 mmol/gbiomass and 34.4 mmol/gbiomass, respectively, at 700 °C. The study concluded that AAEMs played a pivotal role in the gasification reaction. Furthermore, the acid washing-impregnation experiments revealed that the H2 yield could be maximised when the K and Ca loading was 2K-2.5Ca, and the main catalytic role of K in the gasification process and the mechanism of the synergistic gas production by K and Ca were successfully verified.This work provides insights into the K-dominated catalytic process and the synergistic effects of K and Ca in efficient production.

The work has been published in Renewable Energy with a title of "Synergistic promotion of K and Ca in the efficient production of H2-rich syngas from cotton stalks".

Fig. 1 Foliated Ni/Ca3AlO catalysts are used for biomass gasification to achieve high stability hydrogen production

Fig. 2 Schematic diagram of the mechanism of K and Ca co-catalyzed biomass preparation of hydrogen-rich syngas

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina