Enhanced EMI Shielding Performance of Glass Fiber Fabric via Optimized Electroless Copper Deposition

Editor: | May 09,2025

The ever-increasing proliferation of electronic devices, including smartphones, laptops, wearable technology, and communication equipment, has created a critical demand for high-performance electromagnetic interference (EMI) shielding materials to address the challenges of electromagnetic interference and ensure electromagnetic compatibility. Traditional shielding techniques, such as those using conventional metallic shields made of materials like copper (Cu) or aluminum sheets and metal enclosures, face limitations in applications requiring lightweight and flexible materials due to their high density, rigidity, susceptibility to corrosion, and low mechanical strength. In recent years, conductive fabrics have emerged as a promising alternative shielding solution due to their inherent flexibility, lightweight nature, and relatively low cost.

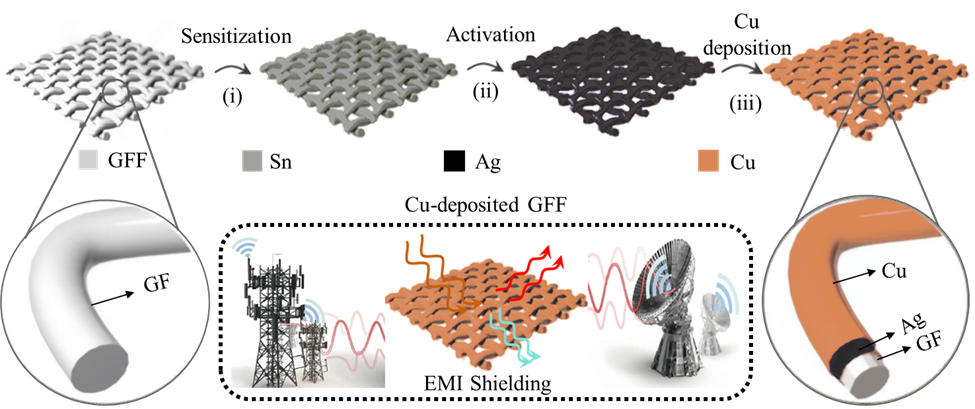

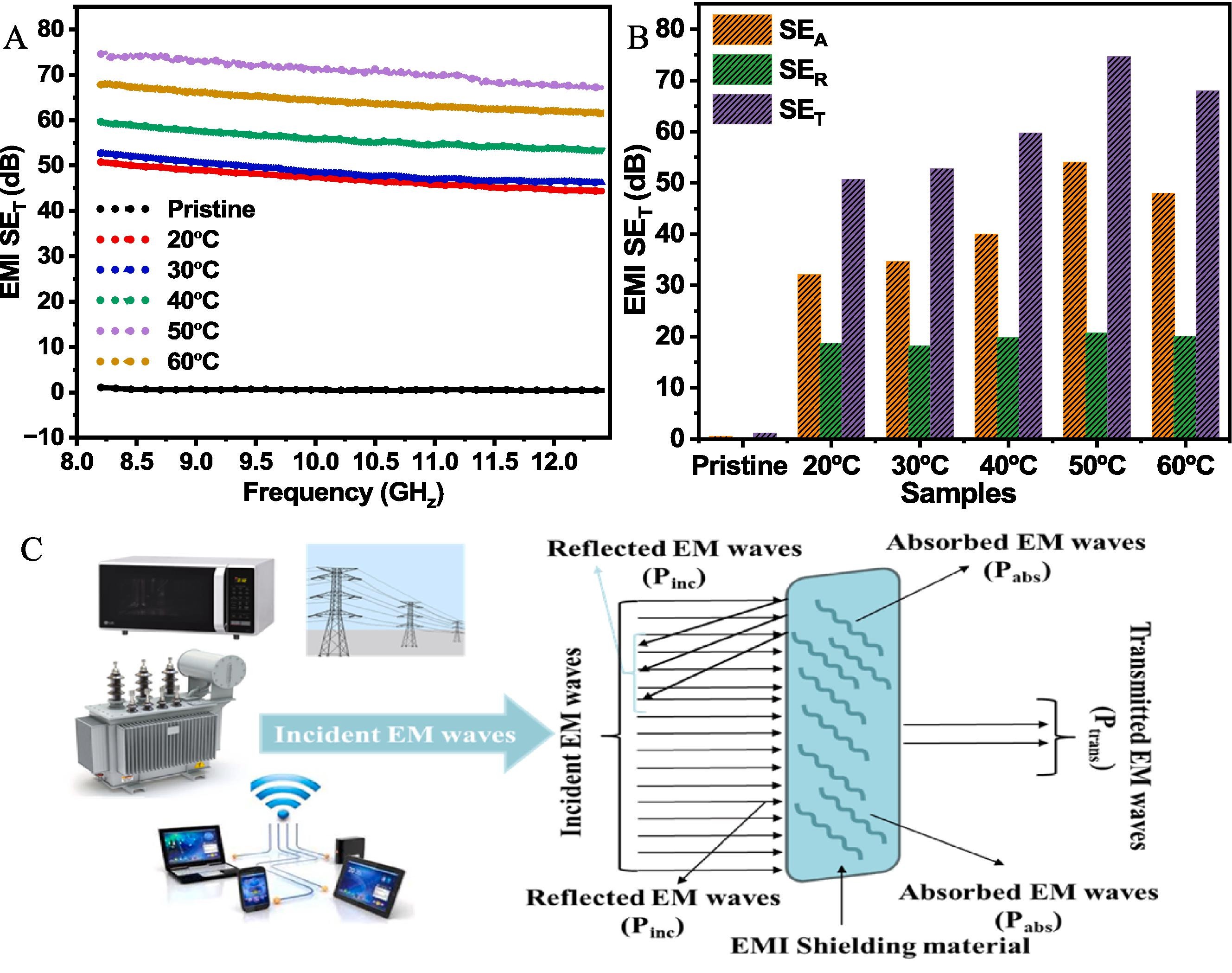

Prof. Abudukeremu Kadier and Peng-Cheng Ma’s group at the Xinjiang Technical Institute of Physics and Chemistry (XTIPC) of the Chinese Academy of Sciences (CAS) developed a novel method for fabricating conductive glass fiber fabric (GFF) via electroless Cu deposition for EMI shielding (Fig.1). Researchers utilized GFF as the substrate due to its advantageous properties, including high tensile strength, heat resistance, fire resistance, durability, and low density. The influence of deposition temperature (20-60°C) on the morphology, electrical conductivity, and EMI shielding effectiveness (SE) of the Cu-deposited GFF was systematically investigated. Experimental results demonstrated that the optimal deposition temperature was 50°C, resulting in a dense and uniform Cu coating with a density of 3.23 g/cm3, a maximum electrical conductivity of 6.41 x 105 S/m, and a total shielding effectiveness (SET) of 74.59 dB (Fig.2). The enhanced shielding effectiveness of the material is attributed to the increased Cu thickness, improved surface coverage, enhanced crystallinity, and strong interfacial interactions achieved at the optimal deposition temperature. Furthermore, the Cu-deposited GFF exhibited enhanced thermal stability, retaining 99.6% of its mass at 900°C.

Notably, the electroless Cu deposition method offers an efficient and scalable route to produce high-performance EMI shielding materials. The resulting optimized Cu-deposited GFF is expected to find broad applications in diverse fields, including electronics, communication systems, smart textiles, protective clothing in high-radiation environments, and advanced aerospace and military systems, offering a vital alternative to conventional metallic shields. The related research findings were recently published as a Research Article in the Journal of Materials Science & Engineering B, entitled “Enhanced EMI shielding performance of glass fiber fabric via optimized electroless copper deposition”.

This work was supported by the Tianchi Doctor Program of Xinjiang Uygur Autonomous Region, Natural Science Foundation of Xinjiang Uygur Autonomous Region, Tianshan Talent Program for Scientific and Technological Innovation in Xinjiang, and the Western Light Program of the Chinese Academy of Sciences.

Fig. 1. Schematic diagram of the fabrication process for electroless Cu deposition on GFF.

Fig.2 EMI shielding performance (A: EMI SET comparison of pristine and Cu-deposited GFF at various temperatures; B: Comparison of SEA, SER, and SET; C: Mechanism of EMI shielding).

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina