Enhanced Mechanical and Electrical Properties of Basalt Fibers through Alkaline Treatment and Electroless Copper Deposition

Editor: | May 22,2025

The increasing demand for lightweight, high-performance materials capable of efficient electrical power and signal transmission is being driven by the growing integration of electronic systems across various sectors. While copper (Cu) has been traditionally favored for its high electrical conductivity and cost-effectiveness, its inherent limitations, such as high density and relatively low mechanical strength, hinder its use in applications where weight reduction and enhanced mechanical performance are critical, including aerospace, automotive, power transmission, and electric vehicles. This has led to extensive research into enhancing Cu properties or developing suitable replacements. One promising approach involves reinforcing Cu with high-performance nanomaterials like carbon nanotubes (CNTs), graphene, and carbon fibers, which can significantly improve mechanical strength, electrical conductivity, and thermal stability. However, challenges such as CNT aggregation, difficulty in achieving uniform dispersion and alignment within the Cu matrix, and the high cost of CNTs and graphene have limited their widespread adoption.

Basalt fibers (BFs), derived from naturally abundant basalt rock, present a compelling alternative due to their high thermal and corrosion resistance and minimal moisture absorption. BFs are composed of silica, alumina, and various metal oxides. Often referred to as the "green industrial material of the 21st century," BFs exhibit high modulus, exceptional chemical stability, and remarkable thermal resistance. Their sustainable nature, attributed to the absence of chemical additives, recyclability, and non-carcinogenic nature, further enhances their attractiveness. BFs have found applications in diverse fields, including road construction, automotive components, and building reinforcement, owing to their high strength, low weight, and high-temperature resistance. However, BFs are inherently insulating, which prevents their direct use in electrical applications. Their relatively smooth surface hinders interfacial bonding with coatings, necessitating surface modifications. Previous research has explored various strategies to enhance BF properties, including incorporating fillers like CNTS, graphene oxide, and polymers. Yet, challenges remain, such as fiber damage during processing, environmental concerns related to certain materials and processes, high processing costs, low electrical conductivity, inconsistent coating quality, and potential accumulation of nanomaterials.

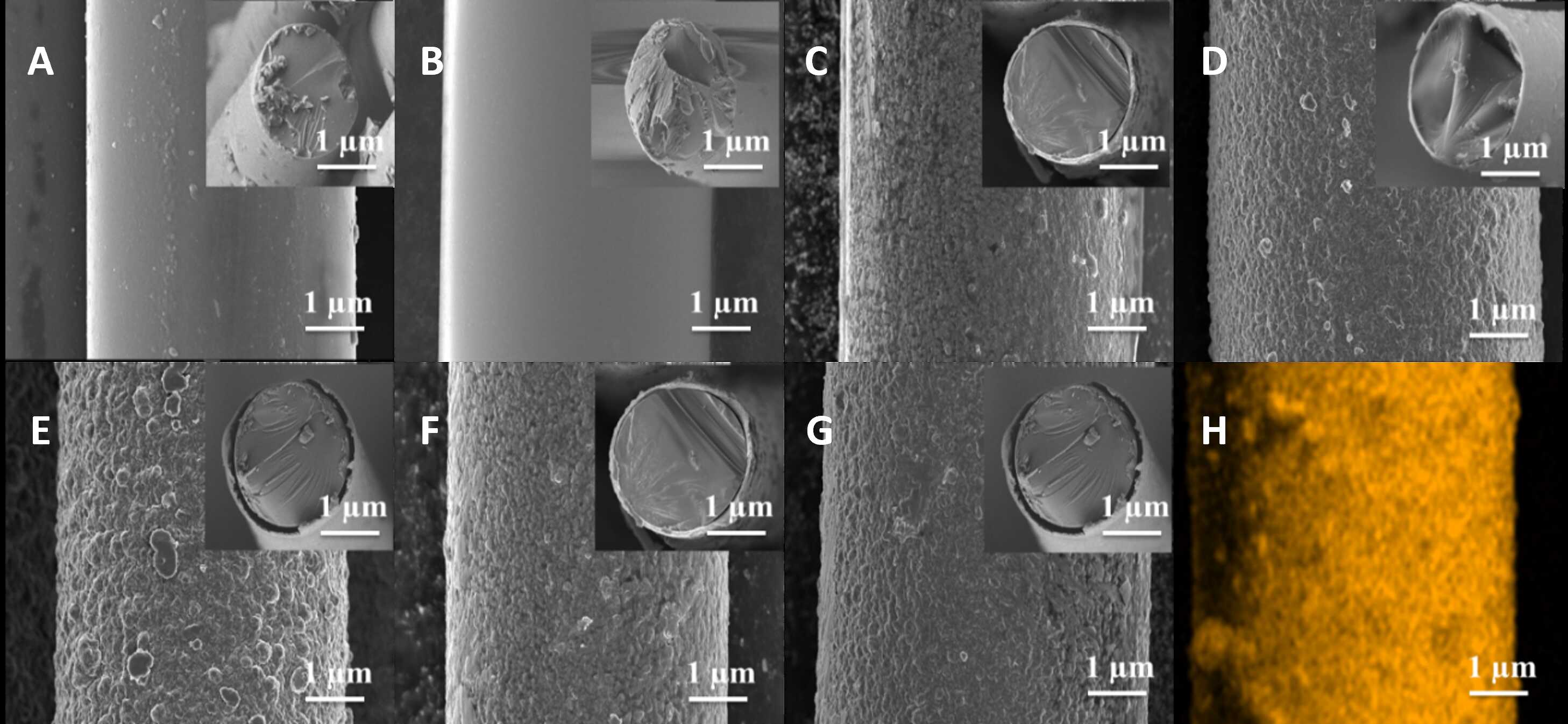

To overcome these limitations, Prof. Abudukeremu Kadier and Prof. Peng-Cheng Ma’s group at the Xinjiang Technical Institute of Physics and Chemistry (XTIPC) of the Chinese Academy of Sciences (CAS) investigated the effects of potassium hydroxide (KOH) and sodium hydroxide (NaOH) pre-treatments, followed by electroless Cu deposition, on BFs properties. While both treatments enhanced the conductivity and tensile strength of BFs, KOH pre-treatment uniquely facilitated improved Cu adhesion and uniform growth. This resulted in a notable 38% increase in tensile strength (1766 ± 392 MPa at 50°C) compared to untreated BFs (1279 ± 301 MPa). Critically, the resulting Cu-coated BFs exhibited an electrical conductivity of 7.82 x 107 S/m at 50 °C, surpassing that of commercial Cu (5.96 x 107 S/m). At the optimal deposition temperature of 50 °C, KOH-treated BFs achieved a density of 3.59 g/cm3, significantly higher than the density of NaOH-treated BFs (3.26 g/cm3) but lower than that of Cu (8.96 g/cm3). The enhanced performance is attributed to the surface morphology induced by KOH, which promotes uniform Cu nucleation and growth. These findings establish KOH-treated, Cu-deposited BFs as promising candidates for high-performance materials, advanced electronics, and next-generation telecommunications, potentially enabling lighter, more efficient, and sustainable technologies for 5G/6G and beyond.

The related research findings were recently published as a Research Article in the Construction and Building Materials, entitled “Enhanced mechanical and electrical properties of basalt fibers through alkaline treatment and electroless copper deposition”.

This work was supported by the Tianchi Doctor Program of Xinjiang Uygur Autonomous Region, Natural Science Foundation of Xinjiang Uygur Autonomous Region, Tianshan Talent Program for Scientific and Technological Innovation in Xinjiang, and the Western Light Program of the Chinese Academy of Sciences.

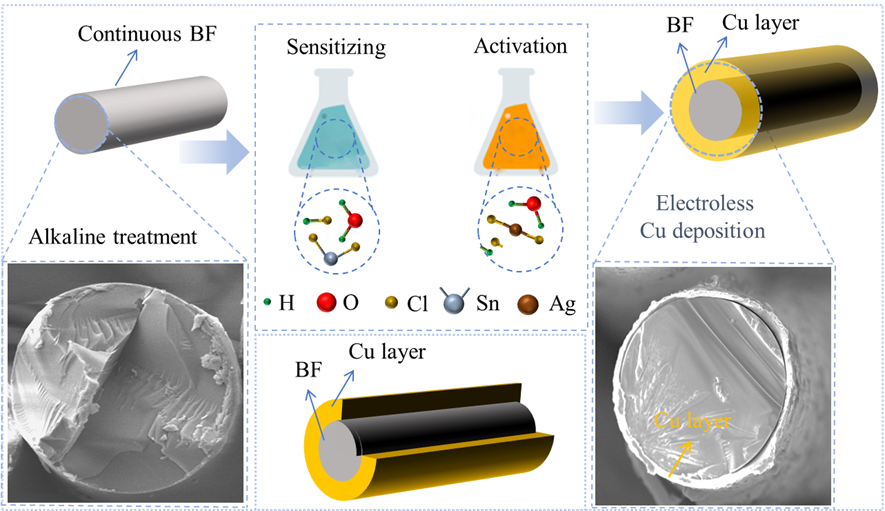

Fig. 1 A novel alkaline (KOH/NaOH)-mediated electroless Cu deposition was employed on continuous BFs, yielding significantly enhanced electrical conductivity exceeding that of commercial Cu and Ag, coupled with a substantial enhancement in tensile strength. This scalable process offers metallized fibers suitable for next-generation telecommunications.

Fig. 2 SEM images of BFs (A: Pristine BFs; B: KOH-treated BFs and Cu-deposited BFs at C: 20 °C; D: 30 °C; E: 40 °C; F: 50 °C; G: 60 °C; H: EDS mapping of Cu-deposited BFs at 50 °C, insert corresponding cross-sectional views).

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina