Progress in Fabrication and Applications of Smart-Responsive Oil/Water Separation Materials

Editor: | Jun 26,2025

In the field of oil/water separation, superwetting membrane materials have achieved widespread application. However, under complex operating conditions, still exist two major technical bottlenecks: 1. Membrane surfaces are prone to fouling, leading to a decline in permeation flux. 2. Traditional materials with single wettability (oil-removing or water-removing types) are struggle to meet the demands for precise regulation, highly efficient separation, and long-term stable operation in complex systems. Hence, the development of advanced smart-responsive oil/water separation materials has become a key research focus in areas such as oil-contaminated water cleanup and efficient separation of complex mixtures.

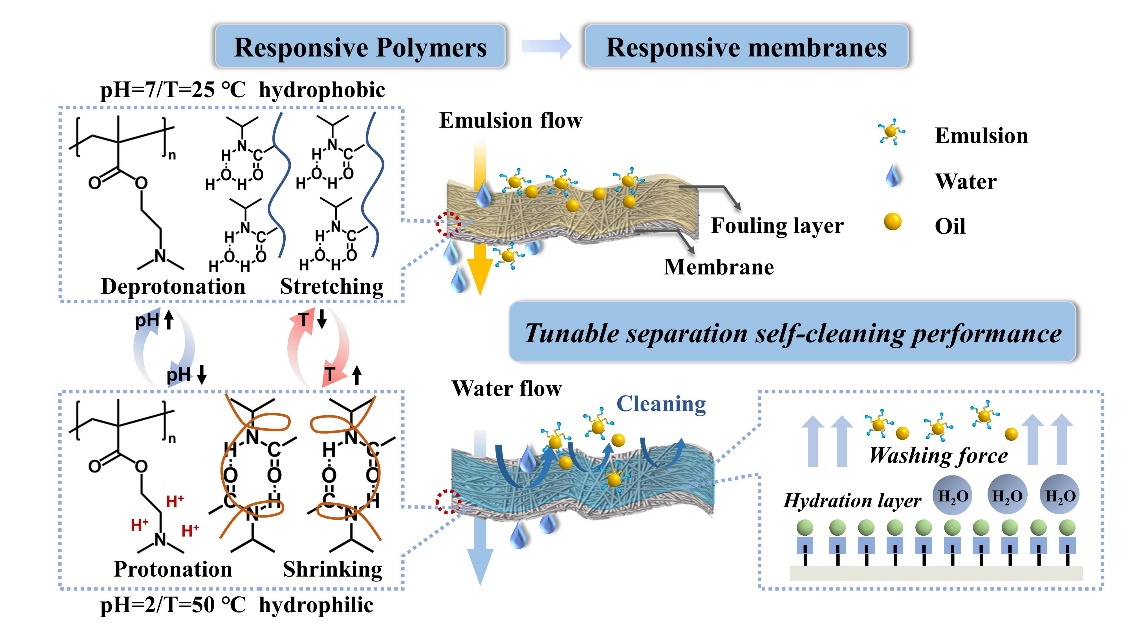

Recently, the Separation Materials and Technology team from the Xinjiang Technical Institute of Physics & Chemistry, Chinese Academy of Sciences fabricated a temperature and pH-responsive fibrous separation membrane through electrospinning of blended stimuli-responsive polymers: poly(N-isopropylacrylamide) (PNIPAM), poly(N,N-dimethylaminoethyl methacrylate) (PDMAEMA), and polyacrylonitrile (PAN). The wettability of the developed membrane is superhydrophilicity at pH 2.0 or 50 °C and presents hydrophobicity at pH 7.0 or 25 °C. This membrane performed excellently in separating various oil–water mixtures, with separation efficiency beyond 99.5% and 96.8% for immiscible oil–water mixture and surfactant-stabilized emulsions, respectively. More interestingly, the temperature and pH responsive wettability could effectively overcome the drawback of flux decline during the separation process. In particular, the membrane has achieved a superior resistance to contamination and a high flux recovery up to 98.9%, related to its greater affinity with water under pH = 2.0/T = 50 ◦C conditions. The related research findings were recently published as a Research Article in the Separation and Purification Technology, entitled "Temperature and pH-responsive electrospun membrane with high flux recovery for emulsion separation". (Separation and Purification Technology,2025, 358, 130247)

Fig. 1. Schematic illustration of the antifouling mechanism in the temperature and pH-responsive membrane.

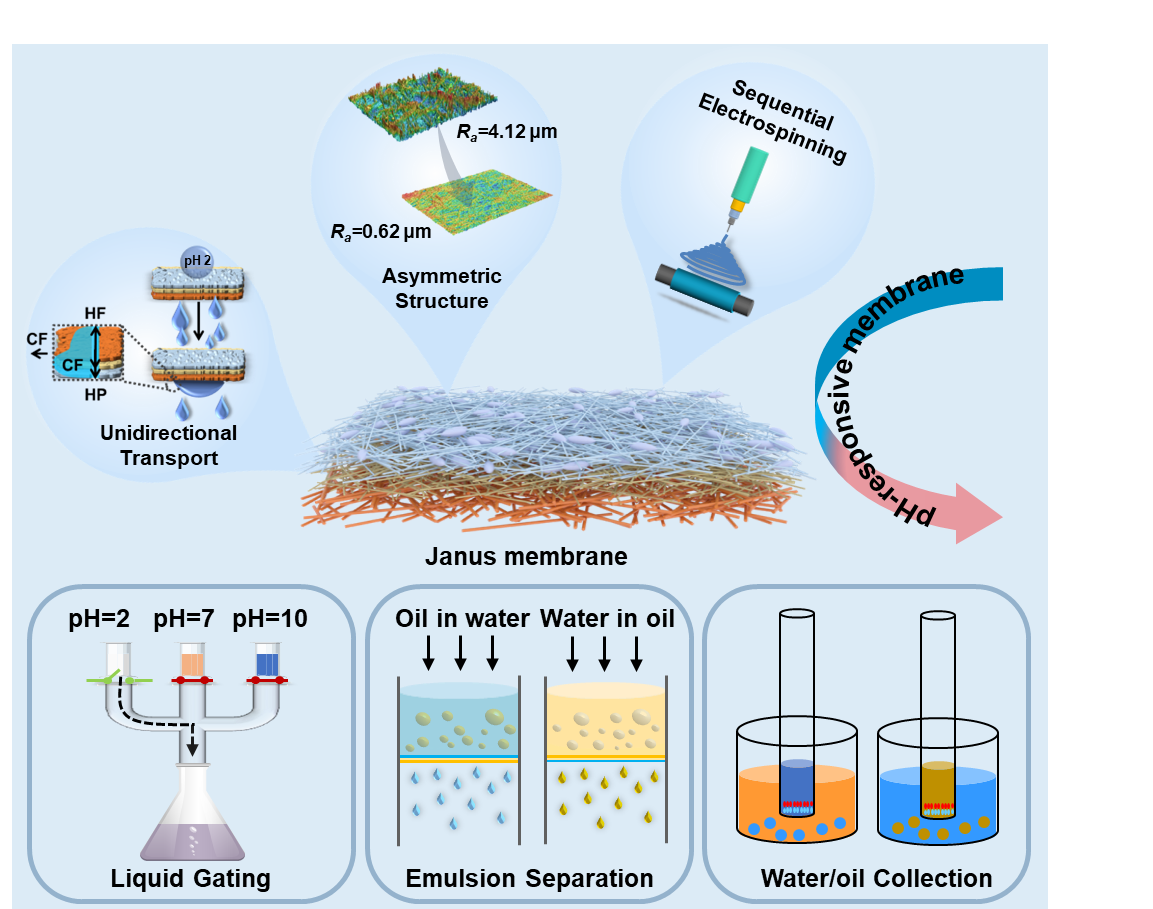

Furthermore, researchers prepared a pH-responsive Janus separation membrane composed of pH-responsive polymers and hydrophobic polymers through sequential electrospinning technology. The top layer of the Janus membrane exhibits a remarkable pH-responsive wettability transition, displaying hydrophilicity at pH = 2 and hydrophobicity at pH=7, whereas the bottom layer maintains a consistent hydrophobicity. This unique asymmetric wettability enabled pH-responsive directional transportation and endowed the membrane with selective liquid gating functionality for acidic solutions. The prepared Janus membrane achieved excellent separation efficiencies of over 99.0% for various oil-water mixtures, including immiscible liquids, oil-in-water emulsions, and water-in-oil emulsions. Based on the unidirectional liquid transport capability, this Janus membrane achieves anti-gravity collection of water or oil from oil-water mixtures without requiring external energy. The biomimetic design and multifunctional integration characteristics of the Janus membrane make it feasible for applications in advanced oil-water separation, on-demand liquid transport, and microfluidic devices. The related research was published in Journal of Membrane Science titled "Preparation of pH-responsive Janus membrane for unidirectional water transportation and efficient oil-water separation". Additionally, the oral presentation based on this research won the Excellent Presentation Award at the 21st Reactive Polymer Academic Symposium of the Chinese Chemical Society. (Journal of Membrane Science, 2025, 733, 124330)

Fig. 2. Schematic illustration of the fabrication and application of the pH-driven Janus membrane.

This research was financially supported by the Natural Science Foundation of Xinjiang Uygur Autonomous Region, the Xinjiang Tianchi Talent Program, and the Xinjiang Key Research and Development Program.

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina