Research Progress in the Melting and Solidifying Behavior of Lunar Regolith simulant in Vacuum

Editor: | Jul 16,2025

The Moon is a reliable and stable "natural space station" for humanity and the starting point for humanity to venture beyond Earth and conduct deep space exploration. Currently, major countries have all proposed their plans for constructing lunar bases (research stations), and how to obtain the materials required for lunar base construction is an urgent issue that needs to be addressed. Utilizing lunar soil resources in situ to build lunar bases can fundamentally address the material requirements for lunar base construction. All currently developed in situ utilization technologies for lunar soil require heating the soil to partial (sintering) or complete melting to achieve soil shaping. Therefore, studying the lunar soil's evolution process and melting characteristics is of great significance for developing various in situ utilization technologies. However, most current in-situ utilization technology research is conducted in Earth-based environments, without considering the vacuum environment of the Moon, and there is limited research on the melting and solidification characteristics of lunar soil in a vacuum.

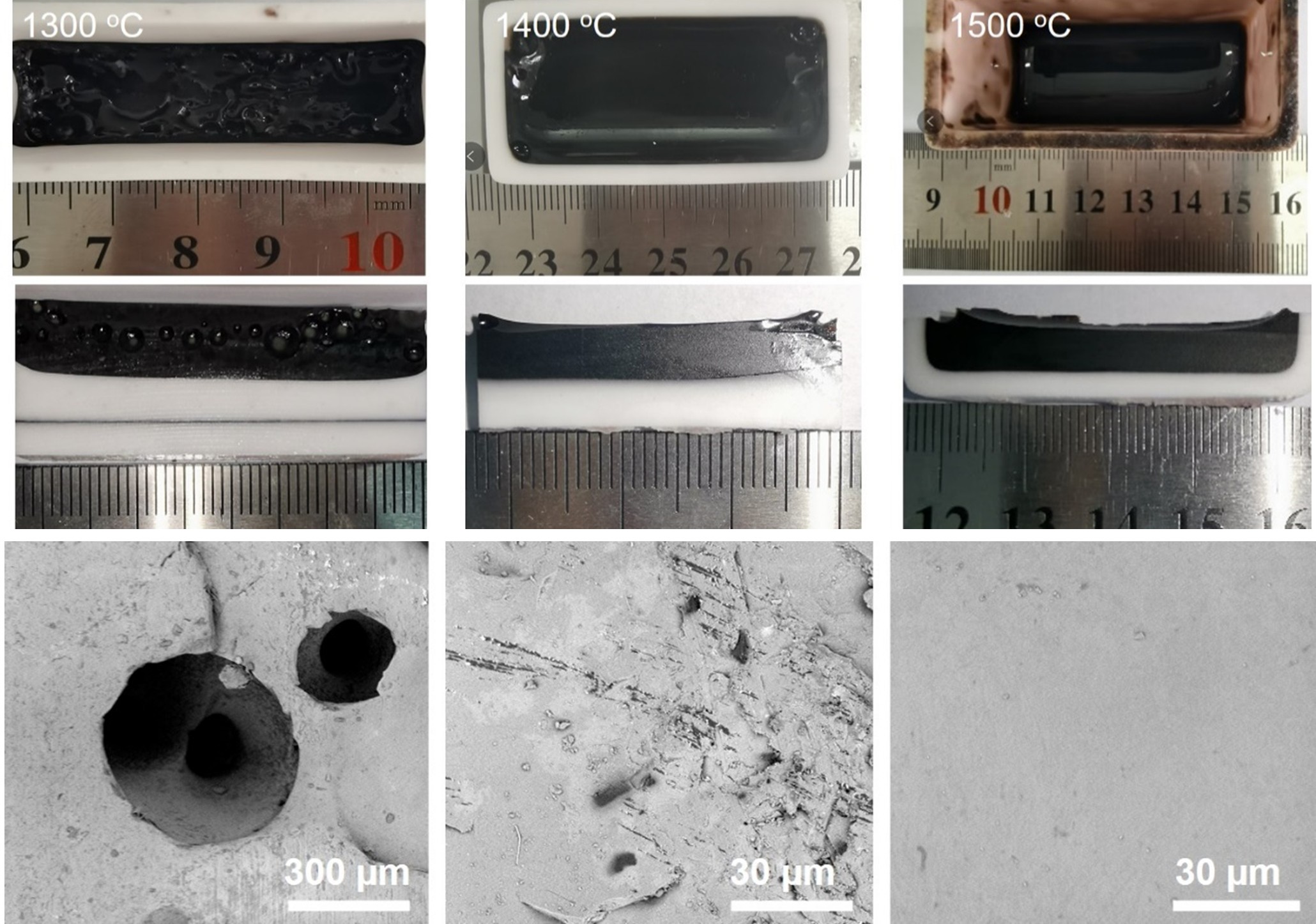

Recently, the Prof. Peng-Cheng Ma’s group at the Xinjiang Technical Institute of Physics and Chemistry (XTIPC) of the Chinese Academy of Sciences (CAS) conducted research on this issue. The study used the CLRS-1 low-titanium basaltic simulated lunar soil national standard sample as the research object, melting it in a vacuum environment at different temperatures (1100 °C, 1200 °C, 1300 °C, 1400 °C, 1500 °C) and solidified it (Figure 1), and studied the morphology, structure, and mechanical properties of the melted process and the solidified sample (Figure 2).

Figure 1. Morphology of samples after melting and solidification at different temperatures in a vacuum environment (Image source: original article)

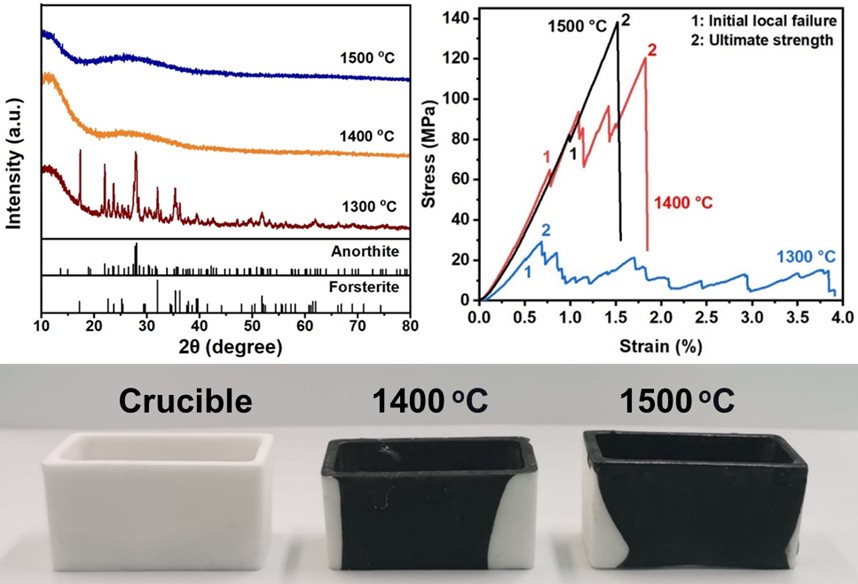

The results indicate that as the melting temperature increases, the density, compressive strength, and Vickers hardness of the cured samples all increase, with the highest compressive strength and Vickers hardness reaching 125.1 MPa and 836.2 (HV0.5/15), respectively. Notably, samples cured at 1400 °C exhibited the highest nanohardness and lowest thermal conductivity, with molecular dynamics simulations indicating that this was primarily due to their more compact atomic structure. Additionally, it was observed that under vacuum conditions, the melt migrates upward along the crucible wall due to the Marangoni effect, and after curing, a dense coating forms on the crucible wall. The above results demonstrate the feasibility of using simulated lunar soil cured via vacuum melting as the construction material for lunar bases, providing theoretical support for the development of future in-situ utilization technologies. Furthermore, the migration of lunar soil melt caused by the Marangoni effect can be utilized to generate coatings on the lunar surface in situ, thereby protecting various materials within lunar bases.

Figure 2 Characteristics of cured samples (A: XRD of cured samples; B: Compressive stress-strain curve of cured samples; C: Migration of melt along the crucible wall due to the Marangoni effect)

The relevant research results were recently published in the Journal of the American Ceramic Society. The research was supported by the National Natural Science Foundation of China, the Xinjiang "Tianshan Talent" and "Tianchi Talents" programs, and other projects.

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina