New Development of Dehydration Materials for Oil

Editor: | Oct 14,2025

Petroleum products serve as the core energy source for the global industrial system, supporting the operation of transportation, power generation, and manufacturing industries. During the transportation and processing of petroleum products, the infiltration of water not only degrades their quality but also affects the safe operation of equipment. Therefore, the development of new materials and technologies for removing water from oil is of great significance. Stainless steel felt (SSF) is often used as a material for oil-water separation due to its excellent corrosion resistance and mechanical strength. However, its inert surface is difficult to modify, making it challenging to maintain its wettability stability over the long term. Moreover, most current oil-water separation methods are limited to one-time separations. In practical applications, oil-water separation often involves more complex processes, such as cyclic separation and gradient separation. However, research on these processes is still relatively limited, and the separation results and underlying mechanisms related to these methods have not been fully explored.

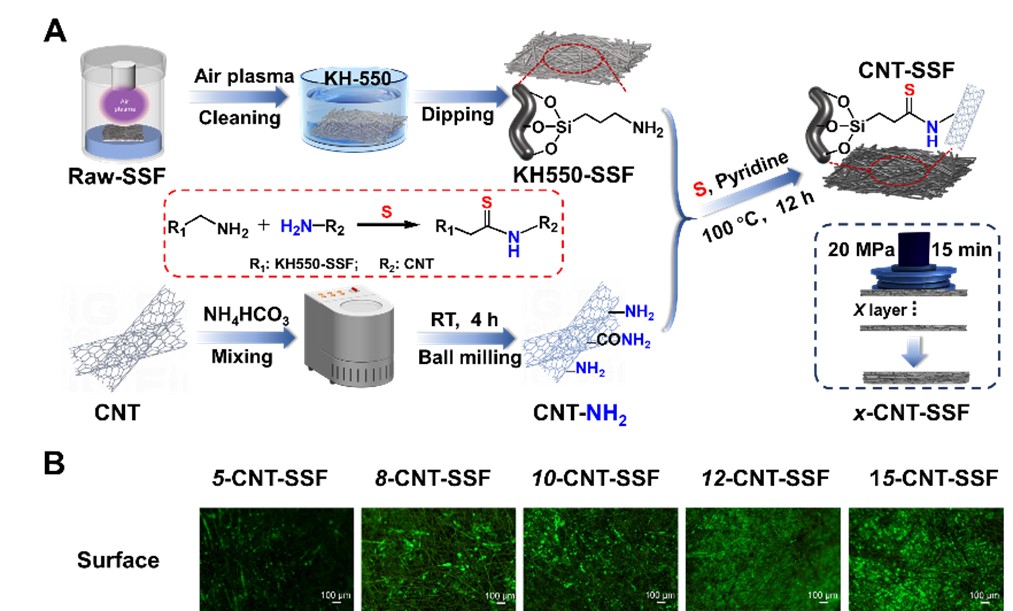

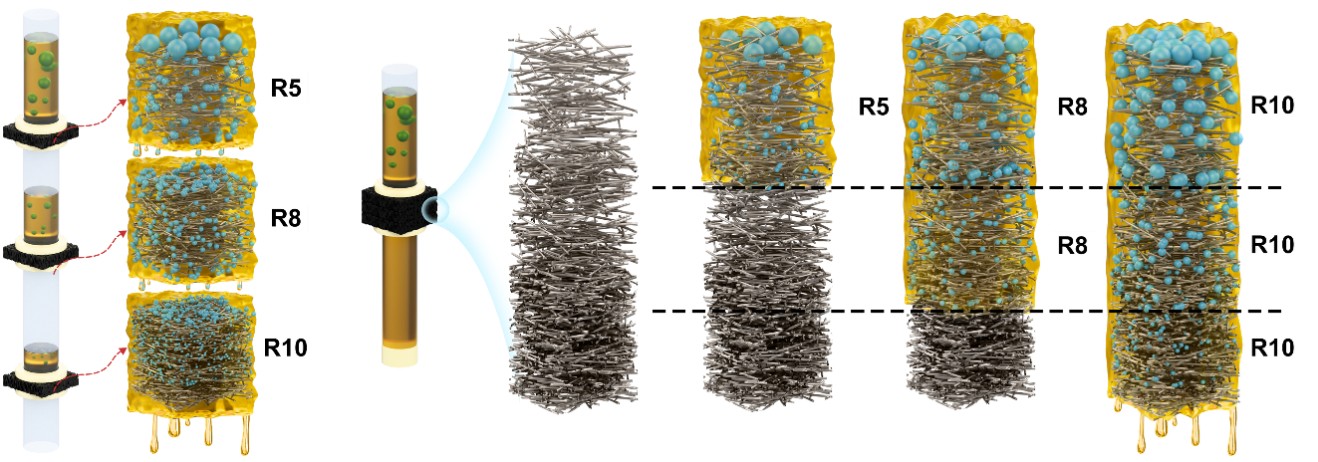

Recently, researchers from the Separation Materials and Technology team at the Xinjiang Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, grafted the silane coupling agent KH550 onto the surface of SSF fibers through plasma treatment and dip-coating. They then loaded amino-functionalized carbon nanotubes (CNT-NH₂) via a sulfur-based three-component coupling reaction, successfully preparing a functional stainless steel fiber felt (CNT-SSF) with stable hydrophobic/oleophilic properties (Fig. 1A). This material exhibits excellent hydrophobic/oleophilic performance, enabling high-flux and efficient separation of various oil-water mixtures, and shows good reusability and stability. By mechanically compressing multiple layers of CNT-SSF, a material with adjustable pore size was obtained, achieving gradient separation of water-in-oil emulsions. It was found that as the number of separation layers increased, the material's pore size decreased, effectively restricting the passage of water droplets and significantly improving separation efficiency. After a single separation with the optimized material, the water-in-oil emulsion became clear and transparent, with a separation efficiency exceeding 94.6%. Moreover, cyclic separation experiments with a single layer of material indicated that water droplets captured inside the material reduced its pore structure, which facilitated the capture of tiny water droplets in the next separation, further enhancing the material's separation efficiency. GeoDict software was adopted to construct a random fiber model and simulate the dynamic separation process of oil-water emulsions with different layers of SSF. The simulations revealed that as the number of SSF layers increased, the water droplet capture ability was enhanced, the allowable particle diameter decreased, and the structural pressure drop gradually increased due to the continuous deposition of water droplets. Visual observation showed that water droplets not only deposited on the surface (Fig. 1B) but also some small-sized water droplets were intercepted and captured by the internal pores, verifying the rationality of the proposed surface pore sieving and internal pore capture mechanisms. Compared with the gradient separation method, multi-stage gradient separation achieved separation efficiency comparable to that of integrated gradient separation. However, the former had a separation flux 1 times higher than the latter, mainly due to the increased resistance during the separation process of the latter (Fig. 2).

This achievement has enhanced the stability of wetting materials through a novel modification method and has investigated the structure–property relationship of materials in the separation of emulsions using various techniques. This work holds great reference value and significance for improving the performance of materials in the field of oil–water separation. The related research has been published in the international academic journal Separation and Purification Technology. The article was authored by Fan-Qi Kong, a master’s student at the Xinjiang Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, as the first author, with Researcher Peng-Cheng Ma and Assistant Researcher Chong-Jiang Lv from the Separation Materials and Technology team serving as co-corresponding authors. The research was supported by the Tianshan Doctoral Program of the Xinjiang Uygur Autonomous Region, the Natural Science Foundation of the Xinjiang Uygur Autonomous Region, the Xinjiang Key Research and Development Program, and the Shanghai Cooperation Organization International Science and Technology Cooperation Program.

Fig. 1 Material Preparation and Result Verification (A: Preparation process of CNT-SSF; B: Fluorescent images of water droplets on the surfaces of materials with different layers)

Fig. 2 Multi-stage and integrated gradient separation mechanism

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina