Progress in Highly Sensitive Ultrathin Temperature Sensors

Editor: | Dec 13,2025

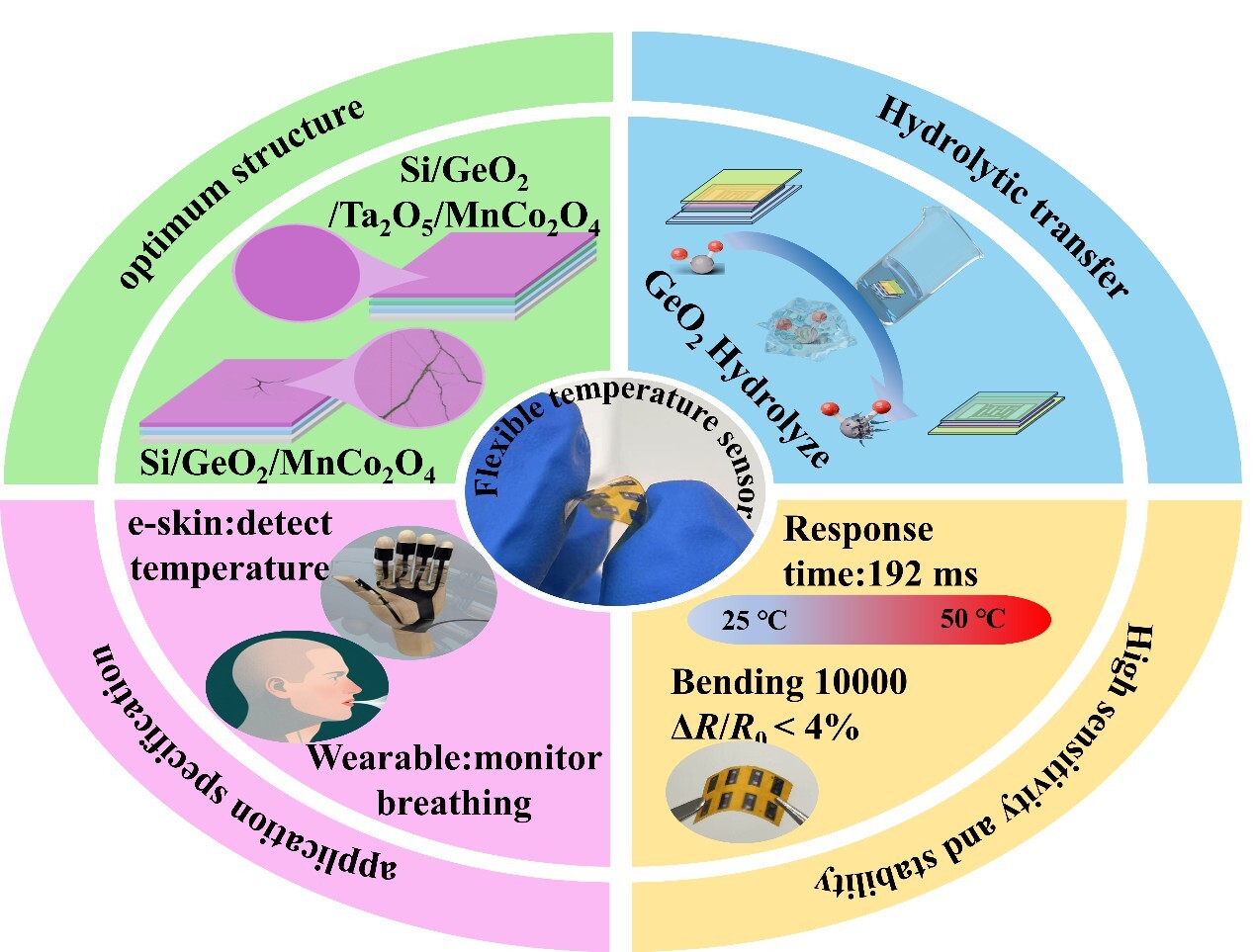

In the fields of intelligent healthcare and robotic sensing, achieving ultra-thin flexible temperature sensors is a core prerequisite for high conformability and integration. However, a fundamental bottleneck persists: the high-temperature processes essential for high sensitivity conflict with the low thermal tolerance of flexible substrates. Consequently, it is challenging for devices in ultrathin form factors to simultaneously achieve high sensitivity, excellent flexibility, and long-term stability.

Recently,the Xinjiang Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, has made significant progress in the field of ultrathin temperature sensors. The research team adopted a "water-soluble sacrificial layer-assisted transfer" strategy, successfully resolving the process compatibility issue between high-performance sensitive materials and flexible substrates, and fabricated an ultrathin flexible temperature sensor with a total thickness of only 40 micrometers.The key of this approach lies in the separation of the high-temperature processing of sensitive materials from their subsequent device fabrication on flexible substrates.This design ensures the necessary high-temperature annealing conditions for the sensitive material while preventing damage to the flexible substrate from high temperatures, thereby providing a reliable technical pathway for integrating high-performance inorganic materials with flexible substrates. To ensure the interface quality after material transfer, the research team designed and constructed a GeO2/Ta2O5/MCO heterojunction interface structure through finite element simulation and experimental validation, achieving active control over the interface properties. This structure effectively suppresses element diffusion and thermal stress mismatch at the interface, significantly enhancing the device's reliability and structural integrity.

Based on the transfer strategy and interface design, the ultrathin sensor exhibits excellent overall performance: its Temperature Coefficient of Resistance (TCR) is as high as -4.1 %/℃, its response time is only 192 ms, and it maintains stable operation under repeated bending and thermal shock. This achievement not only significantly improves the overall performance of ultrathin flexible temperature sensors but also provides crucial technological support for developing next-generation flexible intelligent perception systems such as electronic skin and wearable devices.

The research findings were published in ACS Applied Materials & Interfaces on the title of Water-Soluble GeO2Transferred Ultrathin PI/MnCo2O4/Ta2O5Heterostructures for High-Sensitivity Flexible Temperature Sensors with Extreme Stability with Master's student YAN Xijun as the first author, and Assistant Researcher SONG Yuxian and Researcher KONG Wenwen as the co-corresponding authors. This work was supported by the National Key Research and Development Program, the Xinjiang Tianshan Talents Program and the Natural Science Foundation of Xinjiang Uygur Autonomous Region.

Figure 1 PI/MnCo2O4/Ta2O5 Flexible Temperature Sensor (Image by YAN Xijun)

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina