Research Progress in High-Performance Eco-Friendly Composite Yarn

Editor: | Dec 15,2025

Recently, the Energy and Chemical Engineering Research Center in the Xinjiang Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, has made significant progress in the field of textile materials, successfully developing a basalt fiber/cotton fiber composite yarn that combines excellent weavability with multiple functional properties. It provides a reliable technical solution for the green transformation of the textile industry and the development of high-performance materials.

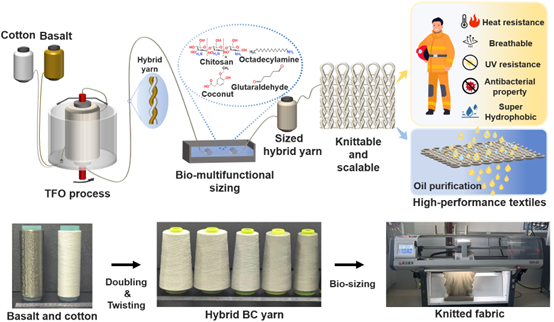

The textile industry is one of the major contributors to global resource consumption and environmental pollution. According to statistics, approximately 85% of textiles eventually end up in landfills. The production process of textiles accounts for about 5%-10% of global greenhouse gas emissions, along with substantial water consumption and the release of chemical pollutants. In response to the United Nations Sustainable Development Goals and to promote green materials and clean production, the researchers combined basalt fibers with natural cotton fibers. Utilizing the “Twist-for-one (TFO)” technology and a self-developed, fully natural sizing, they created a novel composite yarn that is both high-performing and environmentally friendly.

This technology effectively addresses the common industry challenges of brittleness and difficulty in processing basalt fibers by leveraging the flexibility of cotton fibers and the film-forming properties of the natural sizing. The sizing, primarily composed of natural materials such as chitosan and coconut oil, not only exhibits excellent environmental friendliness but also significantly enhances the overall performance of the yarn. Test results show that the strength of the composite yarn reaches 59.6 cN/Tex, far exceeding that of ordinary cotton yarn (14.0 cN/Tex). Fabrics woven from this yarn demonstrate a range of outstanding functionalities: a surface water contact angle of 152.4o, indicating superhydrophobic properties and excellent resistance to penetration by various liquids such as water, milk, coffee, and juice; an ultraviolet protection factor (UPF) as high as 265.3, well beyond daily protection standards; and antibacterial rates of 99.1% and 97.1% against Staphylococcus aureus and Escherichia coli, respectively. Additionally, the fabric exhibits significantly enhanced thermal stability, with an initial thermal decomposition temperature approximately 40 oC higher than that of pure cotton fabric. This material shows broad application potential in areas such as specialized protective clothing, high-performance sportswear, and outdoor functional apparel. The research has validated the entire process of yarn preparation, sizing treatment, and weaving using industrial-grade equipment, demonstrating the feasibility of large-scale production and laying a solid foundation for subsequent industrialization.

This work has been published on Composites Communications, by the title of "Knittable and multifunctional basalt/cotton composite yarn for high-performance textiles". Corresponding author of the work, Prof. Peng-Cheng MA stated, “This work is not only an exploration of a new material but also an important practice in the sustainable development pathway of the textile industry. By integrating natural fibers with green manufacturing processes, we can significantly reduce the environmental impact throughout the entire lifecycle-from production to disposal-while enhancing product performance. This innovation is expected to provide practical technical support for the green transformation of the textile industry.”

Relevant research results have recently been published in Composites Communications. This work was supported by projects including the Scheme of Tianchi Talent on Innovation Leader Introduction in Xinjiang, Western Light Program of the Chinese Academy of Sciences, and Tianshan Talent Program for Scientific and Technological Innovation in Xinjiang, Shanghai Cooperation Organization Science and Technology Partnership Program and the International Science and Technology Cooperation Program. The first author Desalegn Atalie was supported by the CAS-ANSO Scholarship for Young Talents.

Fig. 1. Schematic diagram showing the experimental design and developed hybrid yarns and fabrics

附件下载:

(86) 991-3838931

(86) 991-3838931 lhskj@ms.xjb.ac.cn

lhskj@ms.xjb.ac.cn (86)991-3838957

(86)991-3838957 40-1 Beijing Road

Urumqi, XinjiangChina

40-1 Beijing Road

Urumqi, XinjiangChina