Wind power has become an increasingly attractive source of energy generation in past three decades. It is predicted that the total wind electricity will increase by more than 15% annually in the next 15 years. In order to achieve the expansion expected in this area, there is a strong need for the development of high performance materials which enable the manufacturing of wind blades with larger size. Wind blade represents the most important part in a wind turbine, and it covers more than 20% of a wind turbine cost. In service life, the blades are subject to various external loadings (bending, compression, tension, etc), making the selection of constitute materials for blades a challenge task.

With unique structure and excellent mechanical and transporting properties, carbon nanotubes (CNTs) have attracted much interest in developing multi-functional polymer nanocomposites for various applications. Recently, the polymer nanocomposites team in the Xinjiang Technical Institute of Physics and Chemistry, Chinese Academy of Sciences (XTIPC) analyzed the suitabilities of CNT/polymer nanocomposites for wind blade materials. Special emphasis was placed on the mechanical, fatigue, electrical, thermal and barrier properties of CNT/polymer nanocomposites, which are important considerations when selecting suitable materials for wind blades.

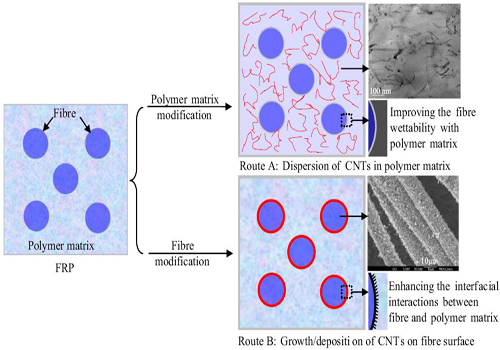

Researchers further explained that the efforts aiming at enhancing the performance of fibre-reinforced polymer (FRPs) for wind blades can be put on modifying the properties of either polymer matrix or fibre. Specifically, CNTs can be incorporated into the materials for wind blades via the following ways: adding CNTs into polymer resins through proper dispersion and processing, and the materials are employed as matrix for wind blades (Route A in Fig. 1); and growth or deposition of CNTs on fibre surface (Route B in Fig. 1), the large surface area of nanomaterials makes it possible to improve the interfacial interactions between the fibres and matrix, thus enhance the overall performance of FRPs. The application of CNT/polymer nanocomposites as sensory materials for the monitoring of defects in composite structures is also discussed. Finally, based on the progress made so far, some suggestions paving the way for the large commercialization of these nanocomposites for wind blades are presented.

The results have been published on Renewable and Sustainable Energy Reviews, 2014, 30: 651-660. Besides, the paper was presented as the plenary lecture at the JEC-Asia 2013 Innovative Composites Summit (ICS) in Singapore in June, 2013.

The work was supported by the Western Light Program of CAS, the 1000-Talent Program.

Fig. 1 Strategies to improve the performance of FRPs using CNTs (Image by XTIPC).