Basalt fibre (BF) is an extremely fine and filamentous material made from basalt rock. Compared with E-glass fibre, BF exhibits much higher mechanical properties and better tolerance to temperature. The cost of BF is much lower than that of carbon fibre (CF), because the production of the former is based on the melting-drawing process.

Thanks to these advantages, BF has various applications in the fields such as filtration, civil engineering, and fibre-reinforced polymers (FRPs). The inherently insulating properties of basalt, however, limits the application of BF for conducting applications.

A research group led by Prof. MA Pengcheng at Xinjiang Technical Institute of Physics and Chemistry of Chinese Academy of Sciences collaborating with Prof. Edith Mäder in the Leibniz Institute of Polymer Research Dresden in Germany utilized BF as a substrate to deposit/grow various carbon-based nanoparticles on fibre surface.

Researchers showed that by controlling the experimental conditions and utilizing the elements in BF, pyrolytic carbon (PyC) or carbon nanotubes (CNTs) were coated on BF surface. The introduction of these nanoparticles led to the turning of insulating BF to the conducting one. When a tow of the prepared BF was embedded into a polymer matrix, the corresponding FRP showed a positive piezoresistance under the mechanical deformation, i.e., the resistance of sample increased with increasing strain.

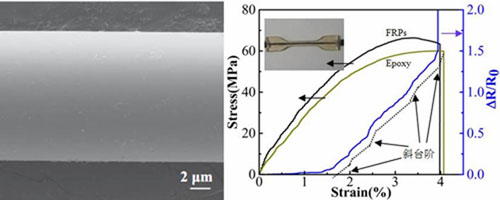

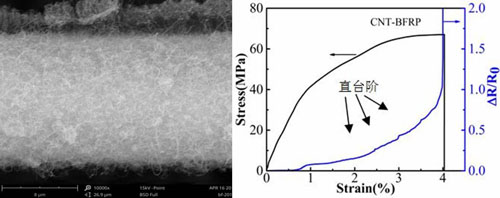

The resistance change (ΔR/R0)-strain curve of FRP with PyC-BF was found to show an tilted-steps (Figure 1), indicating one after another failure of individually conductive fibres in composites, whereas those with CNT-BF exhibited a suddenly jumping behavior in electrical resistance because of the dissimilarities in conductive layer structure (Figure 2).

Researchers further revealed that such behaviors were dominated by several factors, such as the composition and morphology of coating layer on BF surface, the formation of interface, and the wettability between the fibre and polymer matrix.

The novelty of the research lies in the turning of the insulating basalt-based fibre into the conducting one, thus significantly enhance the technical value of basalt fibre. Additionally, by utilizing the method developed by the team, it is possible to realize the production of fibre material with hierarchical structures. The developed material can be used as a potential material to regulate the interfacial strength between the fibre and matrix in FRPs.

The result was published in Composites Part A: Applied Science and Manufacturing. Part of research was presented during the International Conference on Composites Materials (ICCM-21) in Xi’an, China in August, 2017.

The work was supported by the National Natural Science Foundation of China, the Thousand Talent Program and the China-Germany Scientific Cooperation Program.

Figure 1: Basalt fibre with pyrolytic carbon coating and the piezoresistance of corresponding FRPs.(Image by XTIPC)

Figure 2: Basalt fibre with CNT coating and the piezoresistance of corresponding FRPs.(Image by XTIPC)

Contact:

Prof. MA Pengcheng

E-mail:mapc@ms.xjb.ac.cn

Xinjiang Technical Institute of Physics & Chemistry, CAS